12.07-3: Jefferson 1960 10,000 Volt, Electric Spark, Ignition Transformer

| HHCC Accession No. 2006.133 | HHCC Classification Code: 12.07-3 |

|---|

Description:

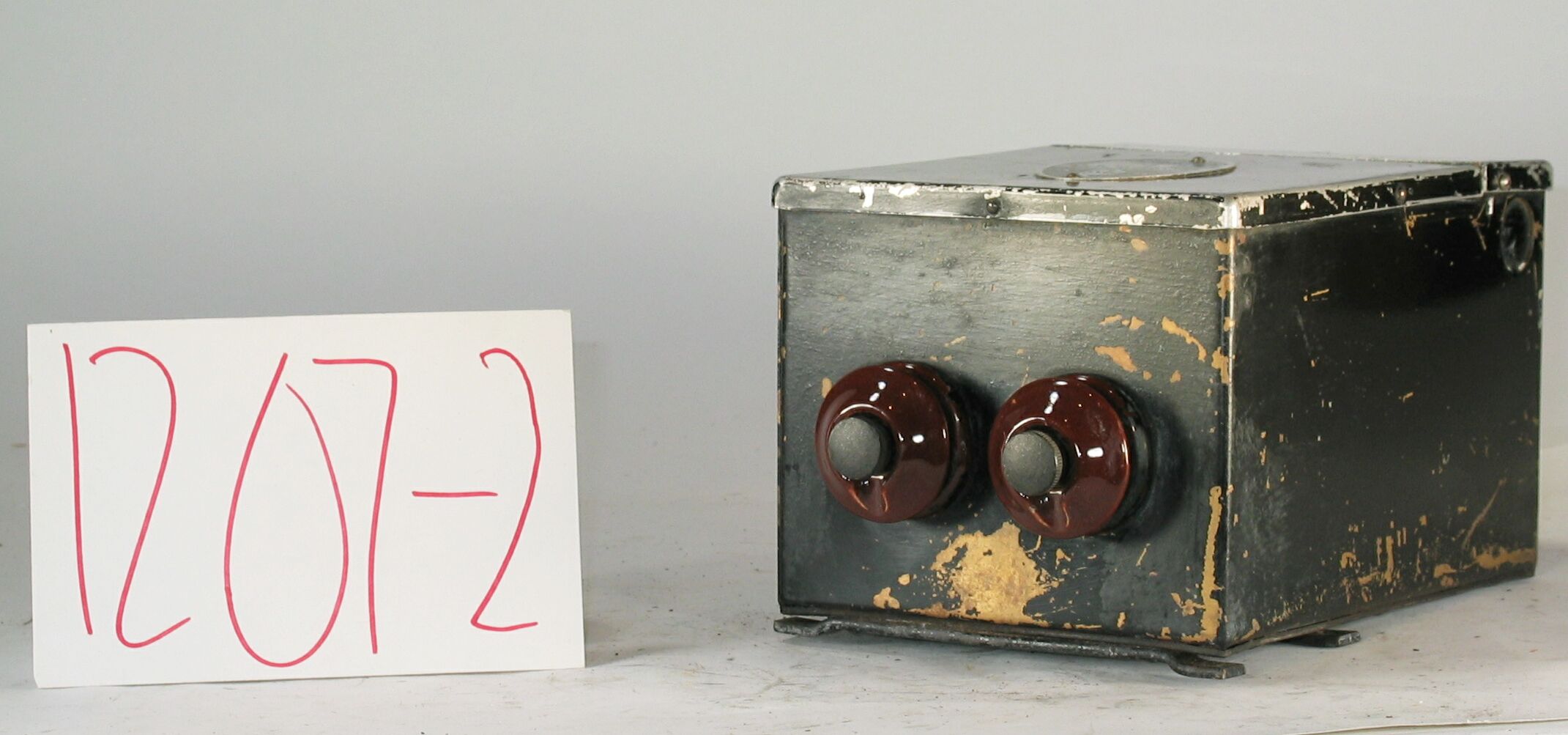

A 10,000 volt, 60 cycle spark, ignition transformer, in ferro-magnetic, steel case in gloss black enamel, with long radius corners, reminiscent of the Art Deco style. Equipped with built in junction box, adjustable base and brown porcelain high tension insulators with screw terminals, it stands as an historic example of the work of early, Canadian, ignition transformer, speciality manufactures, tooling up for the now rapidly expanding, home heating market in Canada, Amalgamated Electric, 1960.

Group:

12.07 Pressure Atomizing Oil Burner Equipment and Systems - Ignition Devices

Make:

Jefferson

Manufacturer:

Jefferson Electric, Amalgamated Electric Corporation, Limited, Torornto

Model:

Cat No. 638-241

Serial No.:

Size:

8 x 5 x 5 in. h

Weight:

12 lbs.

Circa:

1960

Rating:

Exhibit, education, and research quality, illustrating the engineering, design and cultural styling of a mid 20th century high voltage ignition transformer of Canadian manufacture targeted on Canadian oil heating manufacturer’s needs.

Patent Date/Number:

US patents 1777256 [1930]; 1786422 [1930]; Canadian patents 323728 [1932]; 323729 [1932]; CSA Approval 2952

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

10,000 volt output, 60 cycle, 110 volts, 23 mil amps.ignition transformer, Ferro-magnetic, steel case, in gloss black enamel, Chrome plated, name plate with Jefferson logo styled in black and green Art Deco inspired, long radius. rounded corners Built in junction box Brown porcelain high tension insulators with screw terminals Adjustable base slotted for multiple equipment replacement applications.

Construction:

Material:

Special Features:

Original wire connector and cable stub, illustrating electrical trade practices of the times Art Deco inspired, long radius. rounded corners

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

Early high voltage ignition transformers were built in non-ferro magnetic, brass enclosures [See ID# 255 and 256], considered necessary to isolate the enclosure from the electro magnetic circuit. Subsequent engineering studies confirmed the use of magnetic steel shells, as seen here - a cost saving feature for the manufacturer.

By the 1960’s the toe crushing weight of early ignition transformers [See ID# 255 and 256] had been reduced by 50%, due to advances in engineering design, the use of new inorganic dielectric, insulating materials able to with stand high voltages and surges, as well as as a consequence of frequency standardization [25 to 60 cycle]

Industrial Significance:

The smoothly rounded, long radius corners, giving this device a distinctly modern Art Deco look, is also a marker of the advanced, production manufacturing methods of the 1960’s The early patent numbers are somewhat surprising [1930 to 1932], suggest that there was little new in the technology, which could be patented, through the ensuing years to the 1960’s, the major advances being made in materials and manufacturing methods. By the 1960’s the Canadian automatic oil heating industry was into supplying a major after-market, for parts and upgraded equipment. This ignition transformer is a marker of those times, built with adaptable, slotted base-plate, making it readily adaptable to a number of different oil burner manufacturer’s applications.

The increasingly wide range of different physical configurations, as well as different technologies appearing on the Canadian oil heating market by the 1960’s, demonstrated the immense inventiveness characterizing the Canadian automatic oil heating industry of the times. As a result, Canadian ignition transformer manufactures were called upon to adapt their deigns to many different configurations, in order to meet the needs of original equipment manufacturers, as well as the diversity of forms required to economically service the after market [See also ID# 258].

Much of the credibility of the Canadian oil heat industry would rest on its ability to service the after-market promptly, efficiently and at a cost homeowners could afford. Motors, high voltage ignition transformer and electrodes, as well as high pressure oil atomizing nozzles and oil pumps were all casualties of normal ware and tear, often breaking down as a result of prolonged periods of cold Canadian winter weather. A substantial service industry in towns and cities across the country would develop by the 1960’s, with the challenge of maintaining a stock of replacement parts in the many configurations required for emergency, ‘no-heat’ service.

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection