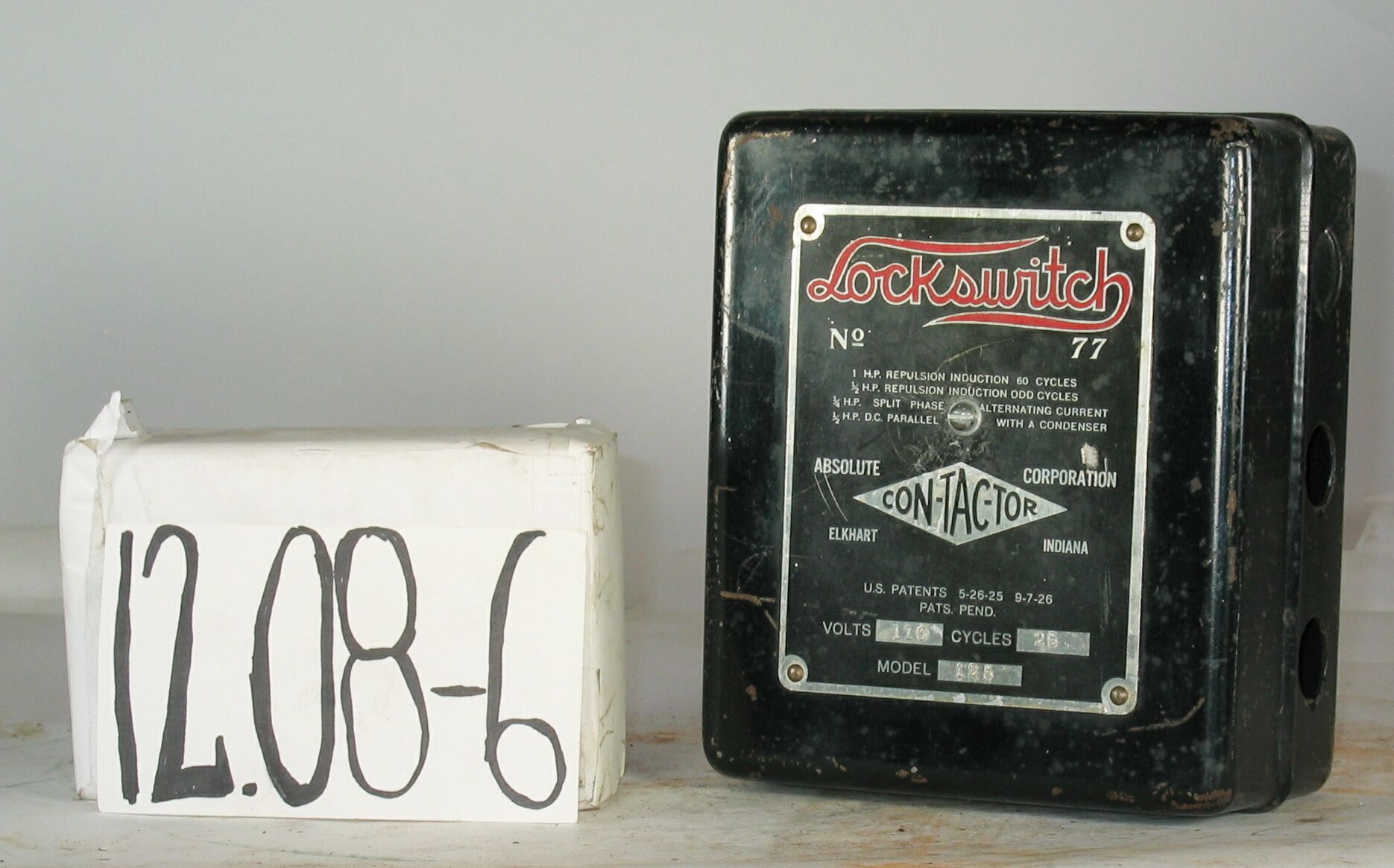

12.08-2: Hart Oil Heat, Preferred Oil Burners 1929 Combustion Controller

| HHCC Accession No. 2006.103 | HHCC Classification Code: 12.08-2 |

|---|

Description:

A 1920’s automated combustion controller for Canadian oil fired, home heating systems, with oil pressure actuated, pancake style bellows safety switch, electric thermal safety lock-out with manual reset and flapper valve actuated mercury bulb switch, enclosed in stylish, heavy cast steel enclosure with highly decorated cover plate, Hart Oil Heat, Preferred Oil burners Inc., Circa 1929.

Group:

12.08 Pressure Atomizing Oil Burner Equipment and Systems - Fuel Flow and Combustion Controls

Make:

Hart Oil Heat, Preferred Oil Burners

Manufacturer:

Hart Oil Heat, Preferred Oil burners Inc., Peoria, Ill.

Model:

Partially obliterated

Serial No.:

Casting No’s: V918; V906

Size:

11 x 34 x 5’ h

Weight:

15 lbs.

Circa:

1929

Rating:

Exhibit, education, and research quality, illustrating the engineering and design of early 20th century combustion controllers for automatic oil heating systems in Canada [ pressure inlet port not included]

Patent Date/Number:

Patents 1245?11; 107?????; 1593564 [1926], numbers partially obliterated

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Oil pressure actuated pancake style bellows safety switch, Open contact copper switch blade with counterbalancing bronze weight Electric thermal safety lock-out with manual reset, Open wound heater strip, nichrom wire wound on laminated mica strip

Unique Cast bronze pressure chamber and orifice with shaft mounted spring loaded flapper valve and tilting mercury bulb, Heavy cast steel enclosure, with moss green enamelled finish Highly decorated cover plate in red, gold and black,

Construction:

Material:

Special Features:

high style, painted stencilled cover plate in red, gold and black Original wiring harness Original oil piping connectors

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

Representative of the earliest automatic combustion control technology for oil fired domestic heating systems marketed in Canada Characteristic of a period of embryonic technological development in any field, this automated combustion controller and safety switch further demonstrates the array of mechanisms, new and novel being experimented with. From the perspective of the early 21st century, without the benefit of documentation or schematic diagram, it is not at all clear even how the various interacting and mutually supporting component parts of this panel operated to variously provide the required level of automation and safety protection required for public comfort and safety. Representative, of the earliest complex systems introduced into the Canadian home. See Note #1

Industrial Significance:

Socio-economic Significance:

As in the case of artifact ID # 226, the appeal of the manufacturer was to the wealthy, those it was thought would be ‘of good taste’. As a result the product was well turned out in an eye appealing, substantial steel enclosure, with smoothly rounded corners to attract the attention of those looking for substance, quality and style.

Socio-cultural Significance:

With combustion safety devices of increasing sophistication and reliability the public’s confidence and trust in automatic heating equipment would increase rapidly, so it was hopped. It was a market of substantial size, but was dependent on the industry to deliver safe and reliable product at a price that Canadians of modest means could afford. The corporate name of the manufacturer, ‘Preferred Oil Burners Inc.’, opulently displayed in gold on the cover of the controller, tells something of the times, the increasingly competitive marketplace for automated oil heating equipment even then developing. A new Canadian culture of comfort and convenience had been triggered and was rapidly evolving in much of Canada by the early 1930’s.

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Cybernetcs and General Systems [Oliver Collection]: Systems Engineering Tools, Harold Chestnut, 1966. Modern Systems Research for the Behavioral Scientist, Walter Buckley, Editor, Aldine, 1968. Systems Behaviour, John Beishon and Geoff Peters, Harper and Row, 1972 Systems Engineering Methods, Harold Chestnut, Wiley, 1977

Notes:

The Introduction of Popular, Complex Systems into the Canadian Home:

The 1920’s saw the introduction of complex mechanical, electric and electronic systems into the Canadian home and the lives of many Canadians, most of them ill prepared. For the first time the public would experience, as an inherent part of their daily life’s routines, the benefits, as well as all too often the vagaries of systems engineering ‘ then in an embryonic state of development. The level of dependence on such systems, with all their inherent imperfections and attendant risks, would be no more apparent than in the field of automatic home heating.

These systems were at once intimidating, awe inspiring, often the source of feelings of personal ineptitude, as well as of fear for reasons of personal and property safety. Included in the early rush to popular technology systems were the automobile, the household radio and automatic home heating. But the most intimidating was, in many ways the latter, immensely obtrusive, in your face, larger than life, and all around you 24 hours a day, bringing with it a degree of dependency that the householder could not afford to forget in the dead of a Canadian winter. All three of these pieces of technology [the automobile, the household radio and the automatic home heating system], have in common an elaboration of interconnected and interdependent parts on which the integrity and performance of the system would be desperately dependent. For the automatic home heating system these components, each with its own unique integrity and operating characteristics, would include, for example: electric motors, flame sensors, solenoid valves, pressure sensors and actuators, electric ignition transformers, heat detecting devices and thermostats. The advent of such increasingly complex, automated systems [mechanical, electric, and electronic] would, in fact, by the late 1940’s lead to a new specialized field of study, known at that time as ‘Cybernetics’, and thence to the larger field of ‘general systems’. The focus was on coming to understand better the properties and performance of complex, inanimate systems, including their degree of purposefulness, self regulation and self direction setting, as well as their ability to communicate meaningful information within the network of which they were a part. For each component of the system must communicate effectively with others for the system to function safely and satisfactorily. System performance, stability, reliability and maintainability, among other criteria, were at stake. All of these criteria were of fundamental importance in the development of automated heating systems for the Canadian homeowner, and the inventors and manufacturers of the day knew it. [See References, General Systems] For their part the manufacturers of these systems, with their myriad component parts and complexities, would learn from the outset the importance of trained service people in communities across the country, wherever such systems would appear. By the 1940’s training courses were increasingly common, as well as control and systems handbooks and systems trouble shooting guides provided by equipment and systems manufacturers.