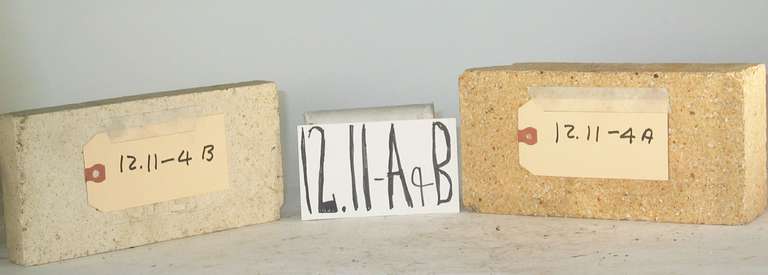

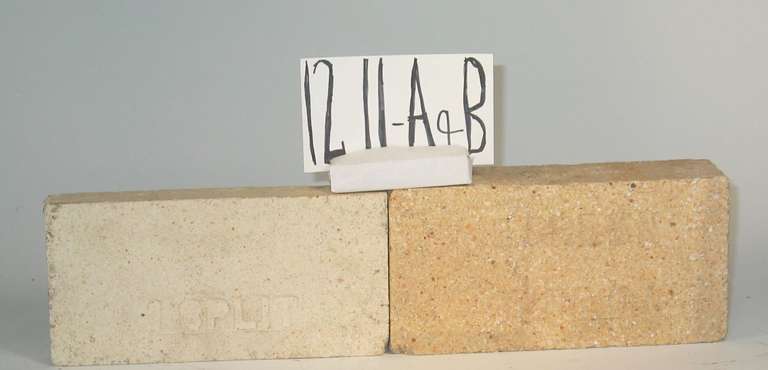

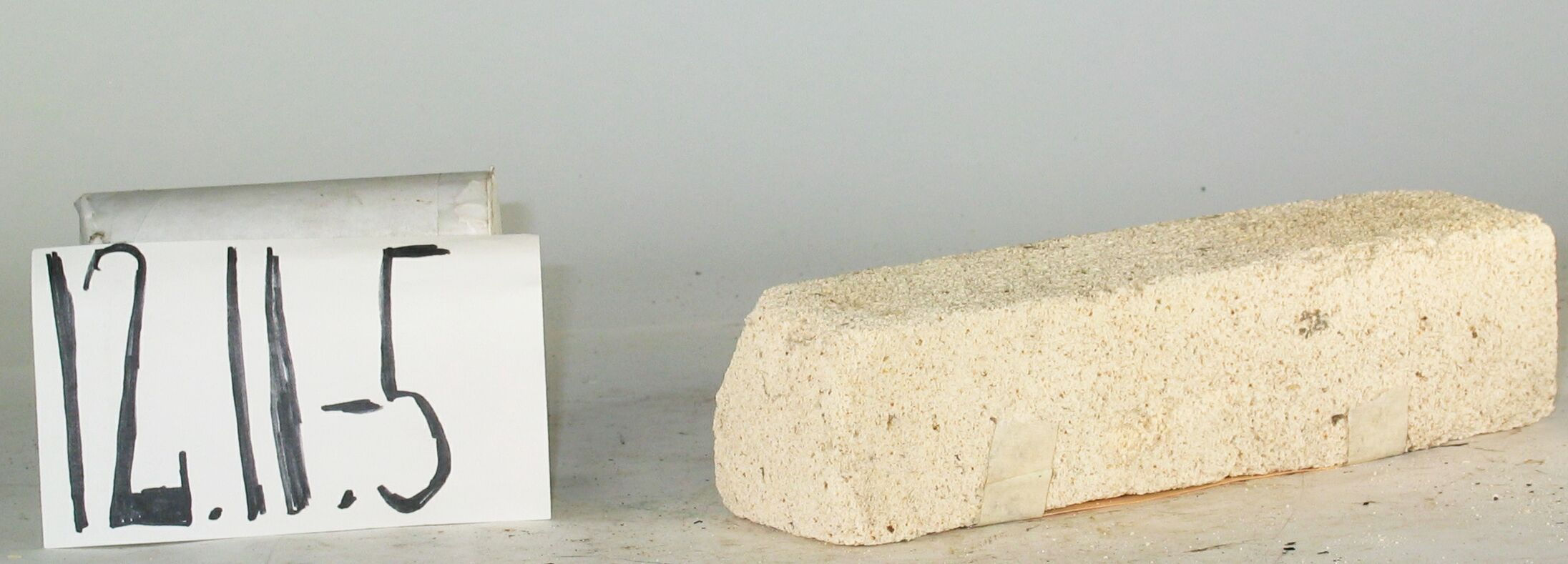

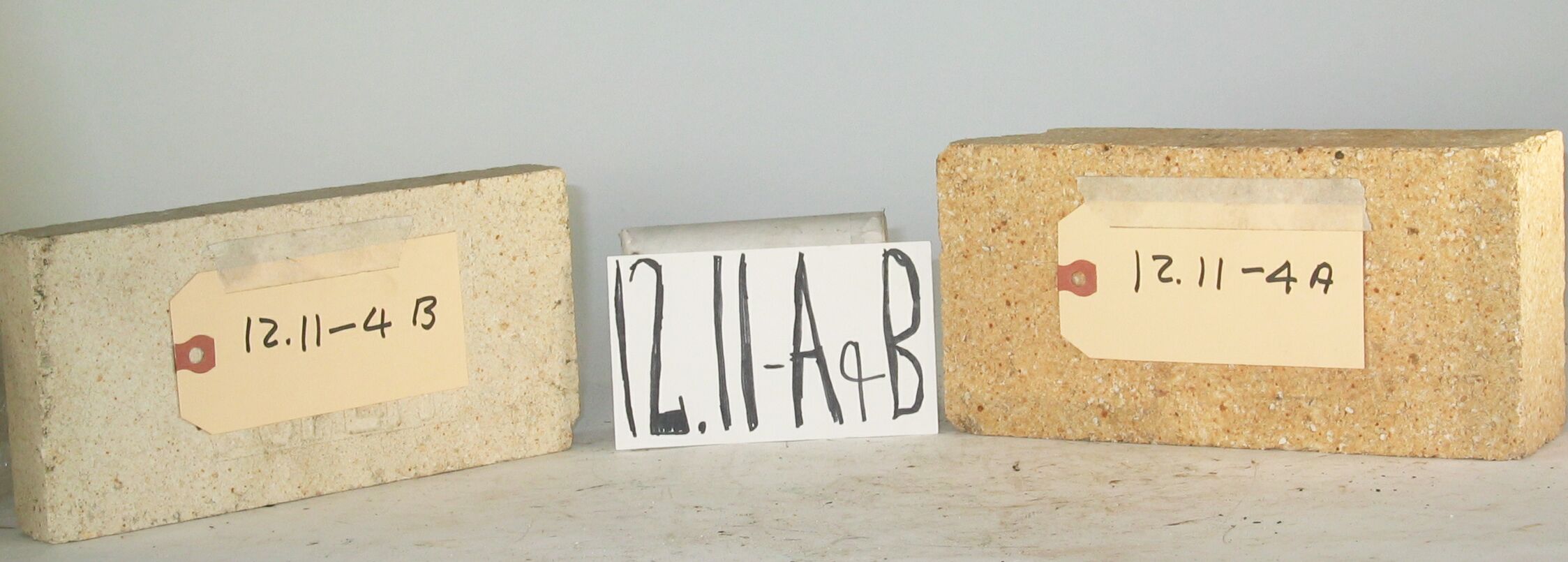

12.11-4: A P Green 1938 High Temperature Fire Brick

| HHCC Accession No. 2006.119 | HHCC Classification Code: 12.11-4 |

|---|

Description:

In the embryonic and early development years of automatic, oil heating systems in Canada, high temperature fire brick were the building blocks of the ‘fire box’ [combustion chamber]. The firebox, holding a 2.600 degree F. flame in check, was a critical component, determining both system safety and performance. It would be skilfully crafted on-the-job, according to the size of the fire chamber, the combustion rate and the unique flame configuration of the oil burner, hard fire brick, A P Green, Circa 1938.

Group:

12.11 Pressure Atomizing Oil Burner Equipment and Systems - Other Components and Parts

Make:

A P Green

Manufacturer:

A P Green, Toronto

Model:

A - Empire DP [full brick] B ‘ Split brick

Serial No.:

Size:

A ‘ 9 x 4.5 x 2.5 in B ‘ 9 x 4.5 x 1.25 in

Weight:

A ‘ 10 lbs. B ‘ 5 lbs.

Circa:

1938

Rating:

Exhibit, education, and research quality, illustrating ‘hard’ fire brick, used as the building blocks of ‘fire boxes’ [combustion chambers], in the early years of automatic oil heating systems in Canada.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Construction:

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

In the embryonic and early development years of automatic, oil heating systems in Canada, high temperature ‘Hard’ fire brick were the building blocks of the ‘fire box’ [combustion chamber]. Shaped much like regular bricks, but made from clays withstanding high temperature

The firebox, holding a 2.600 degree F. flame in check, was a critical component, determining both system safety and performance, a matter of concern for the installer and technician. It would be skilfully crafted on-the-job, according to the combustion rate and the unique flame configuration of the oil burner the size of the fire chamber and the gut feel of the installer.

Industrial Significance:

The construction of fireboxes was an art form of the day, with all to often little for the installer to guide him in a wide range of decisions to be made, effecting the performance of the oil burner and the safety of the system see references Most heating automatic oil heating systems of the 1920’s on into the 40’s in Canada were of the ‘conversion’ type, typically coal and wood fired furnaces and boilers in which oil burners were installed. Wood and coal grates were removed and firebrick used to build a box like configuration, typically, but not always, with a hole at one end to receive the blast tube of the oil burner. With the evolution of the industry came softer lighter fire brick, see ID#244, as well as pre-cast moulded refractory materials, in a range of sizes, pre-shaped for certain firing rates and fire chambers, see ID#245. The significant developments in ceramics engineering, reflected in the refractory materials of the period, should not be understated, for they made possible the evolution of automatic home heating and its seminal contribution to life in Canada. An unobtrusive technology in the public eye, the accomplishments in ceramics engineering tend to get lost in the midst of the Gee-Whiz technological achievements in combustion and electric control engineering of the 1920’s and 30’s. By the 1960’s much ceramic-based combustion chamber engineering would give way to light weight stainless steel configurations, considered preferable for the new world of unitary equipment, pre-tested and shipped to the job site ready for installation.

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Combustion Chamber for Round Boiler, For Model J-R-1 G, Blue print, Fess Oil Burners of Canada, Limited, Toronto and Montreal, undated, Circa 1927 First-Rate Fireboxes, P 10; The Facts about Fireboxes, P13; Hot Flames, P17; To Reduce Pulsation, P.19; ‘Better Oil Heating, A Service Guide, Operation and maintenance of Oil Burners, Fuel Oil and Heat, New York, 1959.