12.12-8: 1938 Pipe Threading Stock and Dies

| HHCC Accession No. 2006.220 | HHCC Classification Code: 12.12-8 |

|---|

Description:

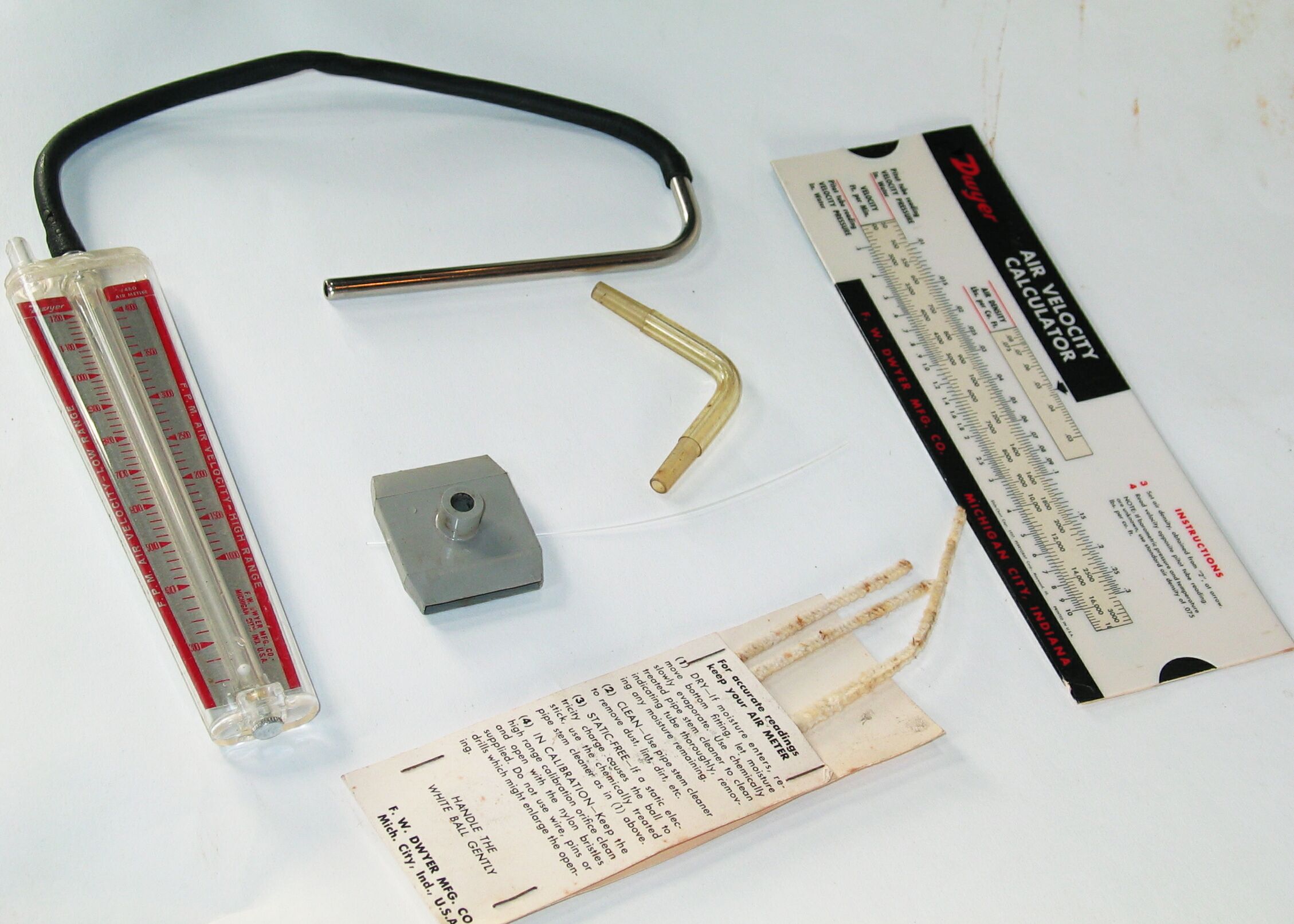

Pipe threading stock and dies, with twin 22 inch stock handles and five dies, !/2 inch to 2 inch IPS with convenient carrying handle. Used for threading iron pipe in the installation of automatic oil heating equipment, part of the increasingly sophisticated tool box of hand operated and hand powered rotary tools required of HVACR equipment installation and service mechanics starting in the late 1920’s, GTD/Reed, Circa 1938.

Group:

12.12 Pressure Atomizing Oil Burner Equipment and Systems - Installation, Test and Repair

Make:

GTD, Reed, as noted

Manufacturer:

GTD, Green Field Mass., Reed Mfg Co. as noted

Model:

No 3

Serial No.:

Size:

53 inch long including stock handles x 5 inches x 4 inch, plus dies

Weight:

30 lbs.

Circa:

1938

Rating:

Exhibit, education, and research quality, illustrating the design and construction of pipe threading stock and dies employed by HVACR installation and repair mechanics in the early years of the industry in Canada

Patent Date/Number:

Pat. 1656596 [1928] Pat 1655596 [1928]

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Hand operated stock with removable 5 dies, ‘ to 2 inches

Construction:

8 lb. GTD, Green Field, steel stock, in red, fitted for twin 1 inch pipe handles, ‘ inch GTD, Green Field, pipe die, No E 122, 14 NPT, R, with No 3, ‘ inch guide ‘ inch pipe die, Reed Mfg Co. Erie P. A. , 14 NPT, 241, H., 3A, with No 3 ‘ inch guide

1 ‘ inch pipe die, GTD, Green Field, 11 ‘ NPT, R, No H831, with No 3 1 ‘ inch guide 1 ‘ inch pipe die, GTD, Green Field, Reed Mfg Co. Pat. 1656596 [1928], 11 ‘ NPT, R, No E 348, 3AP, with No 3, 1 ‘ inch guide 2 inch pipe die, Reed Mfg Co., Erie P.A., Pat 1655596 [1928], No. 30, L, 744, No. 3AP ,with No 3, 2 inch guide

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

This early 20th century, manual, pipe threading stock with dies tells many stories of its times and the changing techynology: The evolution of a new genre of specialized hand tools needed by HVACR installation and service people, starting in the early years of the 20th century The miraculous advances in metallurgy, steels and materials manufacturing and machining techniques achieved by the 1920’s The development of machine standards necessary, for example, in standardising pipe and machine thread sizes and tolerances, The craftsmanship, judgement, and arduous manual nature of much installation and repair work, involving steel pipe, and hand thread cutting, on-the-job.

This tool would be representative of a class of similar hand powered and operated, specialized tools of the period, developed by and for the new, technology-based service trades, starting in the late 1920’s. It was a time well before the introduction of labour saving, motor powered, semi automated pipe threading equipment for field use b y HVACR mechanics. Such hand powered and operated equipment as shown here would be the precursors of much to come, heralding a period of industrial, social cultural and economic change [see below].

Industrial Significance:

This hand powered, arduous pipe threading tool of the 1920’s would be a precursors of much to come. The era of the self powered [electric and pneumatic], self seeking, self regulating and thence fully automated hand tool was still close to half a century in the future for most HVACR field workers - represented, for example, by the electric motor driven, self starting and positioning, power pipe threader, popularly available and affordable for much of the trade by the late 1950’s . But paradoxically, with the evolution of self powered, self regulating and fully automated hand tools would come a significant shift in the skill and knowledge base of HVACR field workers. Many earlier hand skills would be lost, associated with the ‘craftsmanship’ of an earlier period, to be replaced with a focus on labour and time saving and needed economies in installation and service operations in order to reduce consumer costs maintain a competitive edge.

The development of international machine and equipment standards was truly one of the wonders of the period. But, these are stories largely untold - except as evident in such equipment as shown here. A prerequisite to the development of thread cutting dies, for example, was the standardization of pipe sizes, threads and allowable tolerances.

Here a mixture of apparently interchangeable dies, by GTD and Reed make the point. Early machinery and supply company catalogues further suggest the remarkable degree of standardization that had been achieved in the period [see Reference 1]. But the pressure was on for the development of industry machine standards and practices, for the pending consumer market potential was seen to be immense and engineers, innovators and financiers of the period knew it. A substantial machine and tool industry would quickly evolve after W.W.II to support the HVACR installation and service industry. The home service trades grew rapidly during this pre W.W.II period and on into the 1950’s, plumber, electrician, heating and refrigeration. The new, technology-based service trades brought with them a new, quite different breed of industrial service worker, mobile, entrepreneurial, and skilled in the new consumer technologies then available for the Canadian home.

Socio-economic Significance:

Socio-cultural Significance:

With the evolution of self powered, self seeking, self regulating and thence semi and fully automated hand tools, greatly accelerated by W.W.II developments, would come a significant shift in much of the Canada’s socio-cultural infrastructure: For example, the evolution of formal systems for vocational education and technical skill training in Canada [e.g., apprenticeship], would be required to support the technology-based service trades. The evolution of formal vocational skill and technical training in Canada would mirror a movement by then well established throughout much of the Western world [ See References 2 and 3] Following skill training experience in W.W.II, the mid 20th century would see the emergence of the fields of ‘human factors’, systems and the ‘psychology of human learning’, to help provide much needed understandings of conditions for the effective learning of sophisticated motor, cognitive and affective technical and trade skills. [See references 4 and 5]

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Machinery and Supplies, The A. R. Williams Machinery Company, Limited, Toronto, Cat No 48, undated. P. 316 ‘The Development of Education in Canada’, C. E. Phillips, W. J. Gage and Company, Toronto, 1957 ‘The History of Manual and Industrial Education, Charles Bennett, Chas Bennett, Peoria, Ill., Vol.,Up to 1870; Vol. II 1870 to 1917, 1926 For example, see ‘Psychological Principles in Systems Development’, Robert Gagne, Editor, Holt Rinehart and Winston, 1963 And ‘Cybernetic Principles of Learning and Educational Design’, Smith and Smith, Holt, Rinehart and Winston, 1966.