2.01-9: Kelvinator 1936 Four Tray Cooling Unit for Cabinet Refrigerator

| HHCC Accession No. 2003.017 | HHCC Classification Code: 2.01-9 |

|---|

Description:

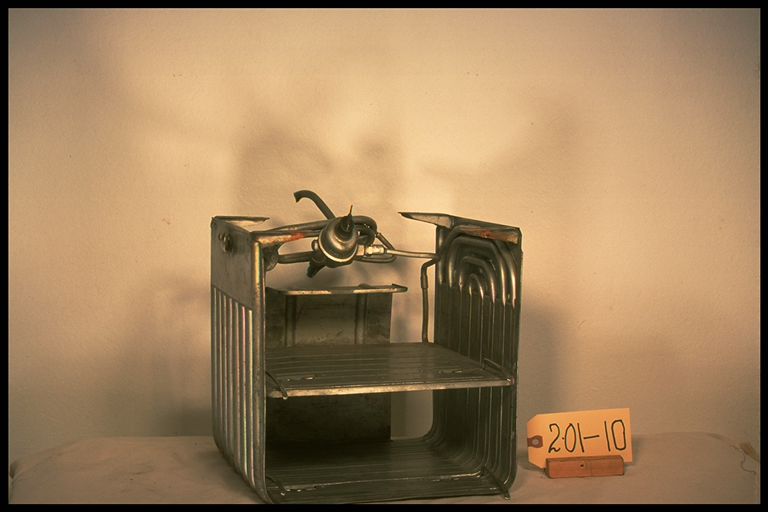

Horizontal, four tray, dry evaporator for high-side float, in formed and rolled steel and heavy white porcelain, ‘high tech’ remote bulb temperature control with defrost and overload controllers and cabinet thermometer, for use on household cabinet refrigerator, Kelvinator, 1936.

Group:

2.01 Refrigerating and Air Conditioning Evaporators ‘ Household

Make:

Kelvinator

Manufacturer:

Kelvinator of Canada, London Ont.

Model:

Serial No.:

Size:

12x 14x 8’h

Weight:

20 lbs

Circa:

1936

Rating:

Exhibit, education, demonstration and research quality. A rare piece of refrigerating hardware, with high tech control features, demonstrating the advancements made in refrigerating engineering, automation and regulation by the mid 1930’s. Also exemplifying the work of a new breed of industrial workers, the industrial designer, of the period.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, commercial and consumer technology.

Type and Design:

Similar to previous item, 016, but without a second fast freezing surface [shelf] this cooling unit is similarly fabricated in formed and rolled steel sheet, to form refrigerant passages, with twin suction line accumulators, An advanced design concept for the mid 1930’s, it offered high heat transfer to meet new performance standards and new found consumer interests of the time. The movement to more integrated and smoothly articulated functional units (evaporators), made up of multiple, individual component parts, each with a life and purpose of its own, is evident.

This cooling unit, like 016 was subject to rapid deterioration due to corrosion of dissimilar materials, as this specimen illustrates.

As for 016, what is new here, however, is also the horizontal pattern adopted by the cooling unit, for central mounting on the top of the refrigerator (See picture from original manufacturers literature appended). The trend to larger cooling units, accommodating the consumer’s interest in frozen foods, was about to significantly alter the way cooling units (evaporators) would be configured in the future.

The cooling unit would grow in size, spreading across the top of the refrigerator, until it occupied the full width of the cabinet and then move downwards to take over an ever increasing percentage of the refrigerated space.

Construction:

A significant aspect of the movement to more integrated and smoothly articulated engineering component design, is coming to see fully functioning components more holistically. Here the cooling unit, originally conceived as a box for ice cubes, with coils of copper tubing wrapped around it, has been re-conceptualised as a single operating entity. Box and coil are now one.

Material:

Special Features:

Gleaming white porcelain finish; full back cooling unit with door in brushed aluminium ( a new designer material of the mid 30’s) with a classic ‘K’ Kelvinator insignia in modern design idiom.

Accessories:

: Ranco remote bulb temperature control, with automatic defrosts switch and manual reset motor overload protector- revolutionary for the times.

Remote bulb, dial reading cbnet thermostat, gave the householder a feeling that they new and were in control of their new, high tech refrigerator

Suction line check valve for high-side float operation. An operating system which itself would be short lived, but one that would be a significant step on the road to increasingly reliable, maintainable, thermodynamically efficient and affordable refrigerating systems for the Canadian household

Inverted flare-tubing connectors, a system developed in the early 30’s, a concept that would be short lived. The system was designed to reduce the bulk of refrigerant tubing connectors and improve the reliability of refrigerant piping.

Remarkable, are the 3 ice cube trays with natural rubber grids, still in tact, in green pigment, with fast cube release mechanism. A 4th tray complete with cover was intended for freezing ice cream .

Capacities:

Performance Characteristics:

The effects of corrosion on the suction line header, resulting from the porcelain on steel construction is evident, leading often to premature failure.

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

See Technological Significance documentation for THOC-HVACR 014, 015 and 016. Like the above, this historical artifact of the Canadian HVACR industry is a remarkable icon of its time, marking a dramatic change in engineering, concepts, manufacturing and styling, as the industry geared up to move well beyond its embryonic development years of the 1920’s.

Of special note is the level of automation and refrigeration system regulation reflected here, in remote bulb temperature controlling, defrost control and motor over load protection (See also historical artifacts THOC-HVACR Group 7.00 ). Seen here are the early manifestations of engineering thought in the practical application of what would become the cybernetic revolution of the 40’s and 50’s, in which mechanical and electrical systems were conceived as purposeful, self-regulating and self-directing entities.

Here, too, the unprepared public would be faced, most for the first time, with a myriad of switches and buttons (three), arrayed on a control panel (not included), which they were expected to understand and use effectively ‘ most did not. The local refrigeration salesman and serviceman, the support network of the times, were constantly on call, if the householder found melted ice-cream, and other dripping contents on opening the refrigerator.

Here, then, are the early manifestations, realised in the engineering concepts and hardware of the period, of the on-coming revolution in the processing of meaningful, purposeful, information through feedback loops. (See ‘Modern Systems Research for the Behavioral Scientist, W. Buckley, 1968) .

Industrial Significance:

This offering was a significant attempt by Kelvinator and the Canadian refrigeration industry to improve system cooling and thermodynamic efficiencies, reduce manufacturing costs and progressively automate and regulate their systems better. The industry was investing heavily in new materials, construction and manufacturing technologies, in order to capture the interests of a second market buyers market.

Socio-economic Significance:

Socio-cultural Significance:

The trend to the ‘gentrification’ of the refrigerator and the kitchens of the nation was on its way, with the appeal to a new generation of urban design tastes, as reflected for example in the cooling unit’s designer door. The trend to gentrification would role on, unabated to the end of the century and beyond.

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection