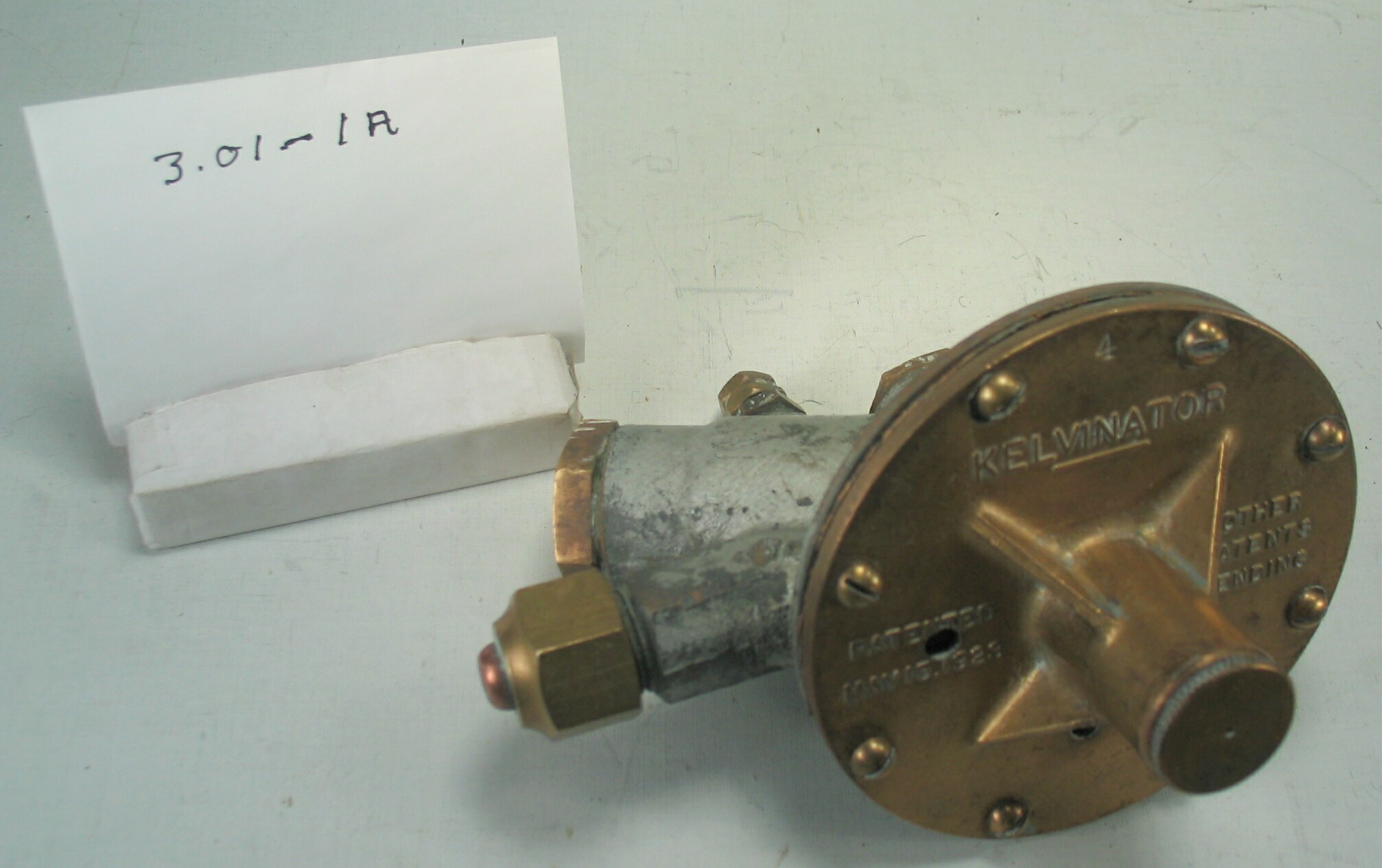

3.01-1A: Kelvinator 1926 Early Automatic, Adjustable Expansion Valve

| HHCC Accession No. 2006.041 | HHCC Classification Code: 3.01-1A |

|---|

Description:

An early, refrigerant flow control, using an automatic expansion valve principle, a pioneering contribution by Kelvinator to the embryonic years of the refrigeration industry in Canada. Handsomely executed in a 5 lb. solid cast brass body and large pressure actuated diaphragm operator, it was engineered for noxious sulphur dioxide, the then newly developed, low pressure refrigerant of choice, Model B1, Kelvinator, circa 1926.

On of a rare set of three similar valves, demonstrating the array of adaptations and applications conceived by Kelvinator for this refrigerant flow control devices, all emerging from the same basic platform. See ID #3.01-1 A, B, C, See Kevinator manuals of the period for depictions of applications and adaptations.

Group:

3.01 Refrigerant Flow Controls - Household

Make:

Kelvinator

Manufacturer:

Kelvinator, Detroit Michigan

Model:

B1

Serial No.:

8001

Size:

7 x 4 x 6 in. h

Weight:

5 lbs.

Circa:

1926

Rating:

Exhibit, education, and research quality, illustrating the engineering design, construction, and operating principles, of quite possibly the earliest refrigerant flow control used in the commercial production of household refrigerators marketed in Canada

Patent Date/Number:

Patented May 15, 1923, other patents pending

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This specimen valve was installed on an early brine tank evaporator in a Kelvinator cabinet refrigerator used in a home in York County [York Region] north of Toronto through the mid 1920’s through early 30’s.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Automatic refrigerant pressure compensated Diaphragm actuated

Construction:

Cast brass body

Material:

Special Features:

Heavy, 5 lb. cast brass body Handsomely embossed with kelvinator logo Over coated with aluminium paint, employing a dispersion of aluminium particles in oil-based paint vehicle, new for the period

Adjustment screw capped and water sealed with knurled brass, screw in cover plate Heavy brass, threaded access ports for the service of internal mechanism The valve was conceived by Kelvinator with a spring compensated, 3” round diaphragm and brass needle seat, and equipped with built-in strainer and pressure adjustment screw, the precursor of much more sophisticated devices to come.

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

A rare specimen of a self-regulating, spring compensated, automatic expansion valve patented by Kelvinator in 1923 and used to maintain cooling units [evaporators], in mechanically cooled refrigerators, at the desired refrigerant pressure.

One of a rare set of three similar valves, demonstrating the vast array of adaptations and applications conceived by Kelvinator for this refrigerant flow control devices, all emerging from the same basic platform. See ID #3.01-1 A, B, C Kelvinator's various manual of the period show the many applications and adaptations that would flow from this basic design concept.

This artifact of history tells the many stories of early adoption of this particular fluid flow technology. After a brief flurry of excitement over the use of costly and delicate float operated devices, as a more efficient means of flow control, industry engineers would return to the automatic expansion valve in the early 30’s. But by then the automatic expansion valve would be a smaller and much more precisely calibrated and efficient device. While the automatic expansion valve was less efficient in its effective use of evaporator surface than high and low side float systems [See HHCC Series 3.01 artifacts], it had the advantage of reliability and price, as well as serviceability. The device demonstrates the manner in which the scientific knowledge, materials and manufacturing methods of the times would come to be used in a refrigerant flow control, popularly appearing in the kitchens of the privileged across the nation. The artifact is suggestive of the problems faced by the emerging refrigeration service sector in Canada. Kelvinator’s service manual, March 1928 gave full details for cleaning and adjustment on which the homeowner would regularly depend, and in turn the manufacturer, for continued customer satisfaction.

Industrial Significance:

Socio-economic Significance:

Socio-cultural Significance:

The socio-cultural significance of the impact of the unobtrusive, automatic expansion valve on life in Canada, throughout the early part of the 20th century, would be hard to over-estimate. It would become the quintessential, automated refrigerant flow regulating device used in homes, farms and commercial refrigeration applications across the country, giving way to other flow control devices, including thermostatic expansion valves and capillary lines, as the century progressed. It was a period in which machinery in the home was often not at all welcome, being viewed with the suspicion that comes with novelty. Machinery belonged on the farm and on the factory floor, but not in the Canadian home. Here it was considered noisy and hazardous, a potential threat to personal and private property. The mere notion of a self regulating, mechanical device that could be trusted to stop and start and self regulate itself reliably, over long periods of time was simply not part of popular experience of Canadians of the time. Thus, in addition to the immense array technical problems which remained to resolved, there was an equally large array of socio- cultural challenges to be over come by manufactures in convincing their public to be early adopters of refrigeration technology in the home - in the face of massive mistrust and apprehension. Conversely, for those that were in a financial postion of enjoying the many benefits of the technology, there were multiple factors tending to attract advocates. Included were: the human need to be seen as an early, recognized leader in adoption, the need for socio-economic status in the community, as well as the allure of new taste sensations, a break with overwhelming, desperate boredom of the daily dietary offerings of the period.

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Kelvinator Service Manual, Copywrite 1928, Kelvinator Detroit Mich.

Notes:

Related Reports:

CMx02, CMX04 exhibit catalogues