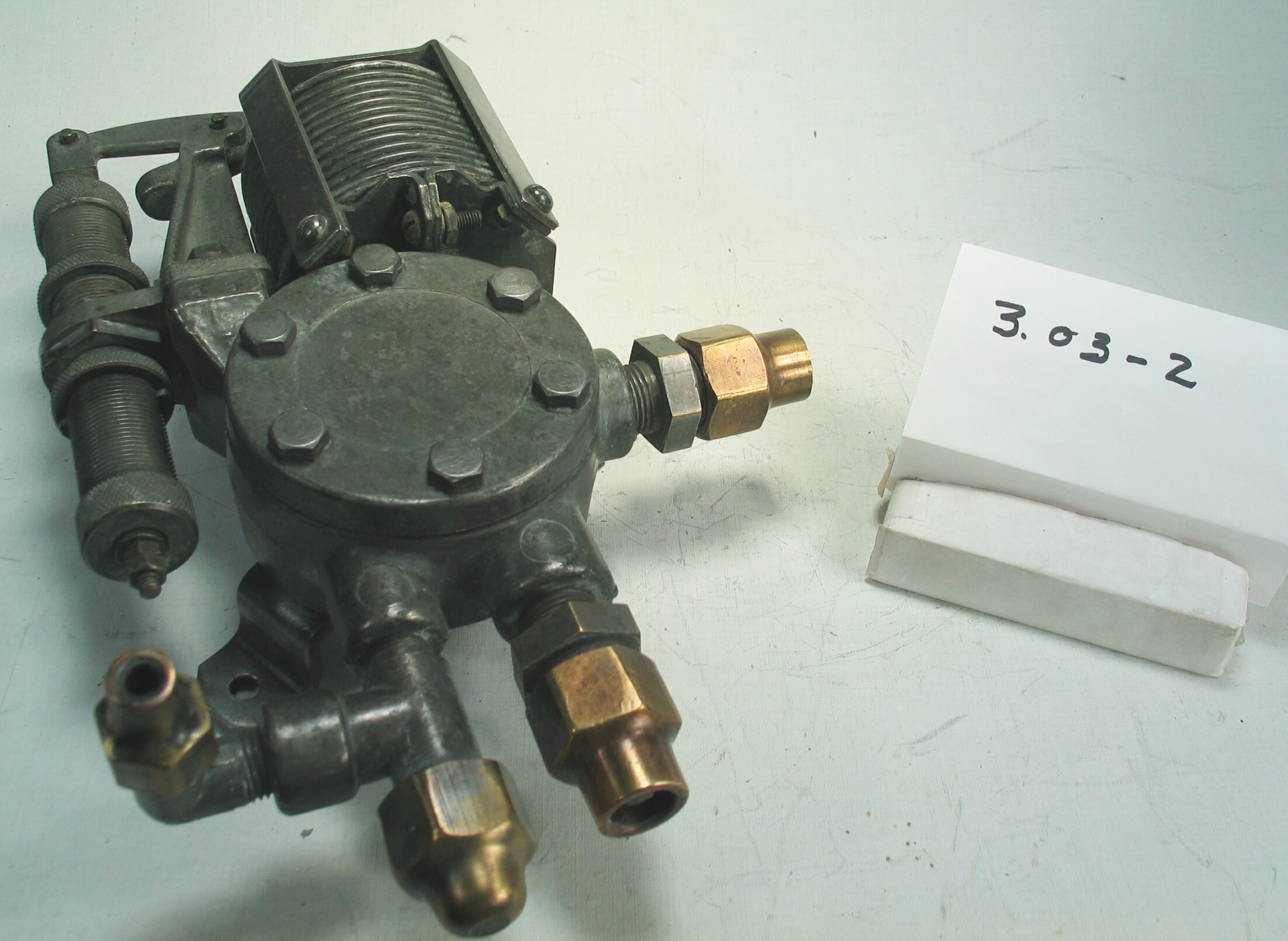

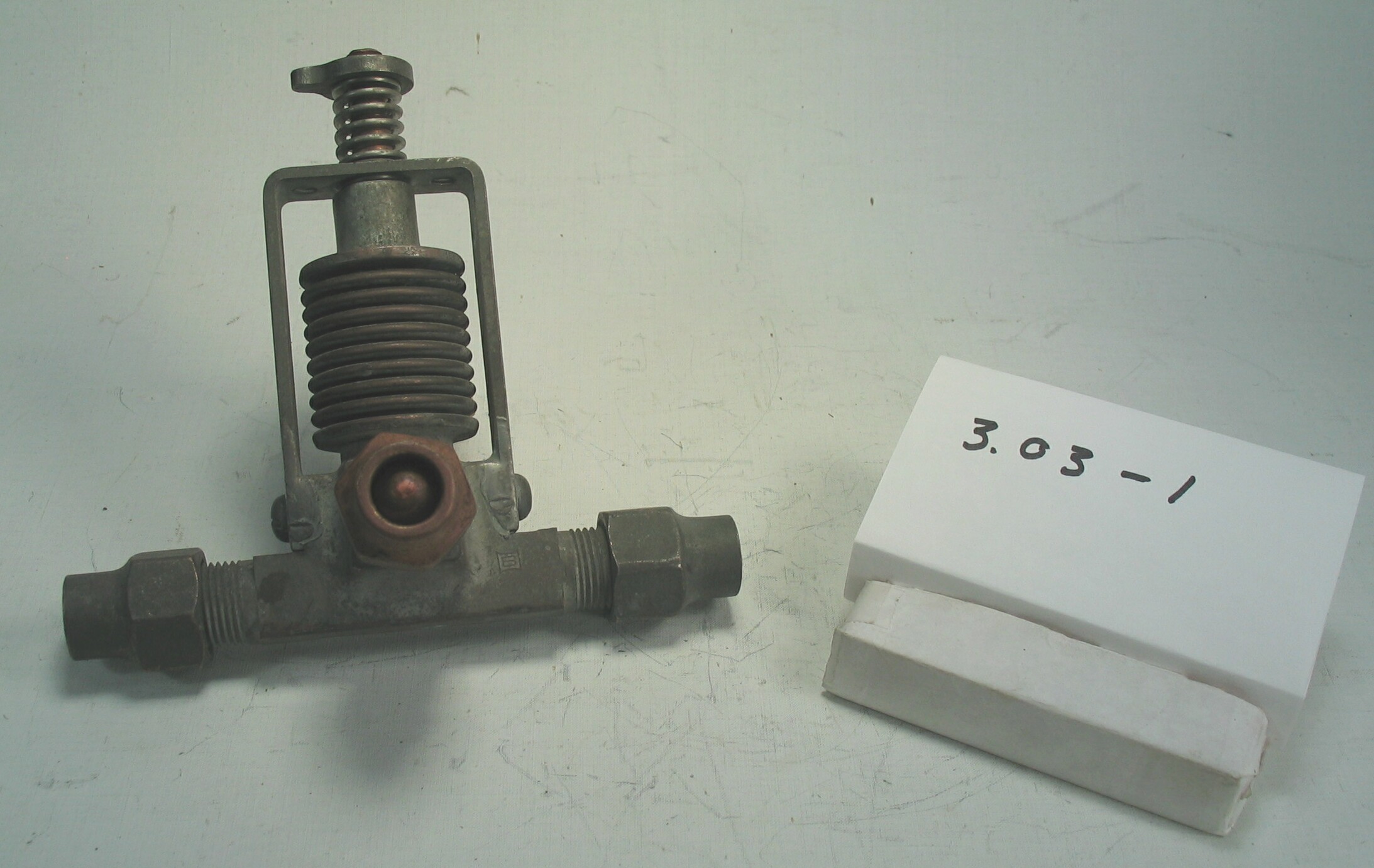

3.03-9: Automatic Products 1955 Electro-Magnetic Flow Control Valve

| HHCC Accession No. 2006.076 | HHCC Classification Code: 3.03-9 |

|---|

Description:

A Canadian produced, 1950’s electro-magnetic solenoid, refrigerant flow control valve for low pressure refrigerant applications, with brass body and press formed, ferro-magnetic cover fitted with heavy ‘ inch electrical connection boss, large capacity with sweat connections and manual lift, handsome nameplate and logo in red and silver, alternating current, 60 cycle, 115 volt, Automatic Products, Circa 1955

Group:

3.03 Refrigerant Flow Controls - NEC

Make:

Automatic Products [AP]

Manufacturer:

Automatic Products Corp., Cooksville, Ontario

Model:

270

Serial No.:

Size:

6 x 3 x 8’h

Weight:

6 lbs

Circa:

1955

Rating:

Exhibit, education, and research quality, illustrating the engineering and application of electro-magnetic solenoid switching, refrigerant flow controls in operation in the early post W.W.II years

Patent Date/Number:

2222419 [US 1940]

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

- 60 cycle electro-magnetic

Construction:

- brass body

Material:

Special Features:

Original lead seal carrying the AP logo Stylish name plate and company logo in reds and silver The art-deco styling of the 1930’s had disappeared to be replaced by the simple functional styling characteristic of the 1950’s, Manual lift feature would be a selling point to engineers and service personnel responsible for maintaining system operation in the event of electrical malfunction Precautionary installation instructions cast in brass body, indicates the delicacy of these devices and the challenge facing manufacturers in educating field service and installation personnel of Heavily stressed brass body tells something of the life and times of the valve, the problems in installation and service of the device. Plastic electrical insulated leads, new for the 1950’s was a marker of the longer life expectancy for theses devices

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

With a simpler more functional and smoother look, this device is, in many ways, representative of the advancements in engineering and styling changes in refrigeration component technology between the 1930’s and 50’s.

More sophisticated manufacturing processes, backed by more engineering design know-how and the availability of new synthetic dielectric insulating materials and finishes all lead to a world change in look and in the reliability of performance. For historic context see ID # 196-197

The increased use of the Freon series of refrigerants, F12 and F22 encouraged the development of valves with larger and larger capacities, as illustrate here

Industrial Significance:

This valve is a marker of a unique period in the evolution of the Canadian refrigeration industry. Manufactured in Cooksville Ontario. It would mark the rapid expansion of the industry in the early post W.W.II years, with a sense of opportunity that went with the times. While relatively short lived, AP opened a small manufacturing/assembly operation in Cooksville to take advantage of developing markets. It should be noted, however, that the patent number is an American number - as might be expected.

Refrigerant flow control quickly became a matter of interest for refrigeration system design engineers in the 1930’s with the development of low-pressure refrigerants and a growing market for small versatile, mechanical refrigeration systems - able to operate multiple evaporators, often at different suction temperatures. The suction pressure regulating valve was one solution [See ID # 192, 193, 194]. The solenoid valve with electric pressure or temperature actuated controller was another option awaiting development.

From the 1930’s thorough 1950’s the industry produced electric solenoid valves in a wide variety of configurations and sizes, to perform a wide range of system functions, each with different performance requirements and characteristics, each manufacturer bringing to the market place his unique approach to engineering design and construction. Some of these are illustrated in the collection ID # 196 to 200:

ID # 196 ‘ Penn, brass body, 3/8 IPS, 7/32 orifice, 60 cycle, dual voltage 115/230 volts AC, 14 watts, adapted for two point mounting bracket, circa 1939

ID # 197 ‘ Penn, brass body, 3/8 IPS, 7/32 orifice, 25 cycle single voltage 115 volts AC, 14 watts, adapted for two point mounting bracket, circa 1939

ID # 198 ‘ Detroit Controls, brass body, 3/8 flare, 3/16 orifice, 60 cycle single voltage 130 volts AC, 15 watts, Circa 1953

ID # 199 ‘ General Controls, steel body, 3/8 IPS inlet, 3/8 outlet with brass half union connection, 177 port, 60 cycle single voltage 230 volts AC, 14 watts, Circa 1960

ID # 200 - Automatic Products [AP], brass body, with manual lift, ‘ inch sweat, inlet and outlet, 3/8 orifice, 60 cycle single voltage 120 volts AC, adapted for single point mounting bracket, 16 watt, Circa 1955

Socio-economic Significance:

For cost considerations, in the era of ‘open’ refrigeration systems, in the late 1920’s through to the pre World War II years, a popular practice was to operate two or more evaporators, even those at different temperatures, on a single condensing unit, a design known as multiplexing. The design of multiplexed, commercial refrigeration systems was a significant part of the evolution of the early 19th century Canadian commercial refrigeration industry. The electric solenoid valve played a major part in this evolution, changing Canadian’s expectations of the range of fresh foods and confectioneries available from there local friendly down town merchant.

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Marshall Refrigeration Co. Ltd., Catalogue circa 1955, P63 Handbook of Engineering Fundamentals, Section 8-24,Ovid W. Eshbach, John Wiley and Sons, 1936