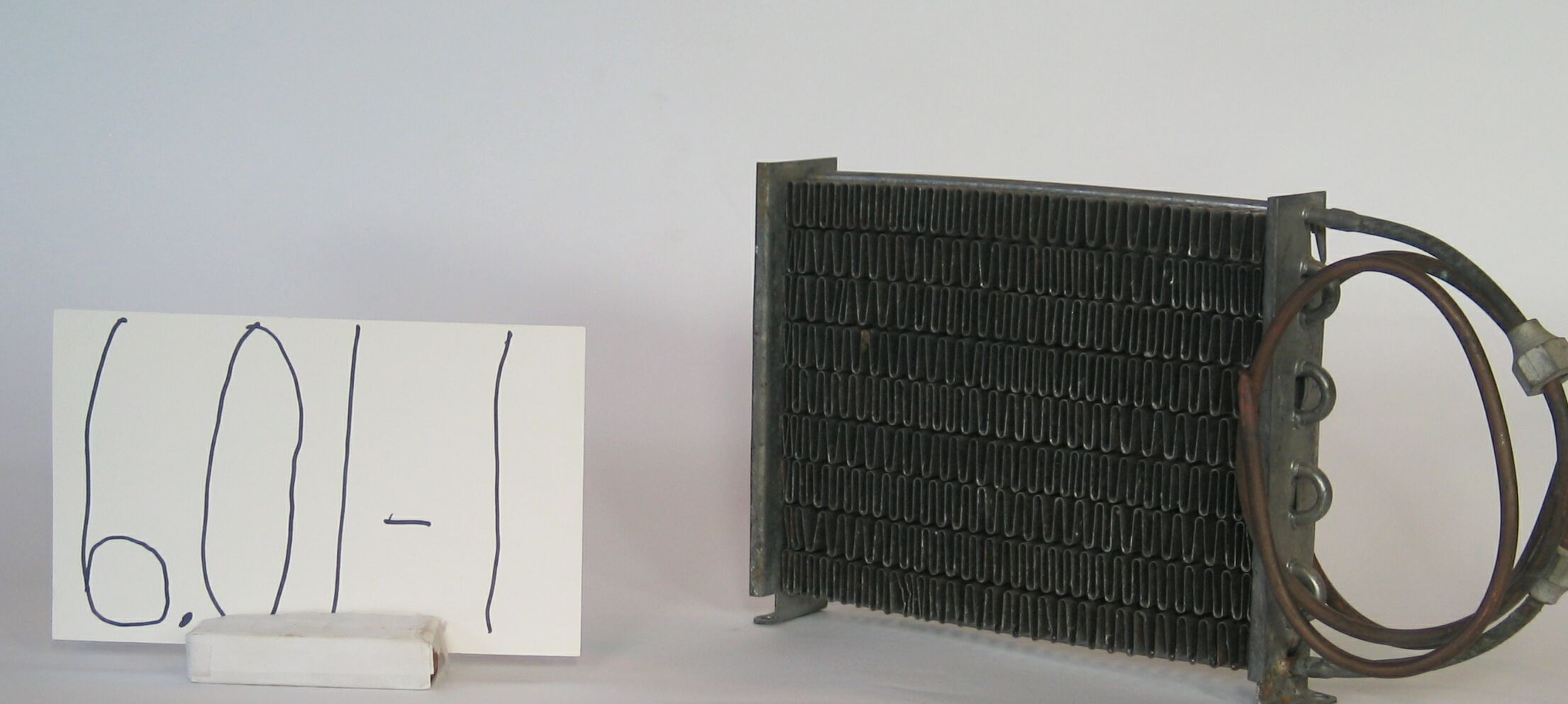

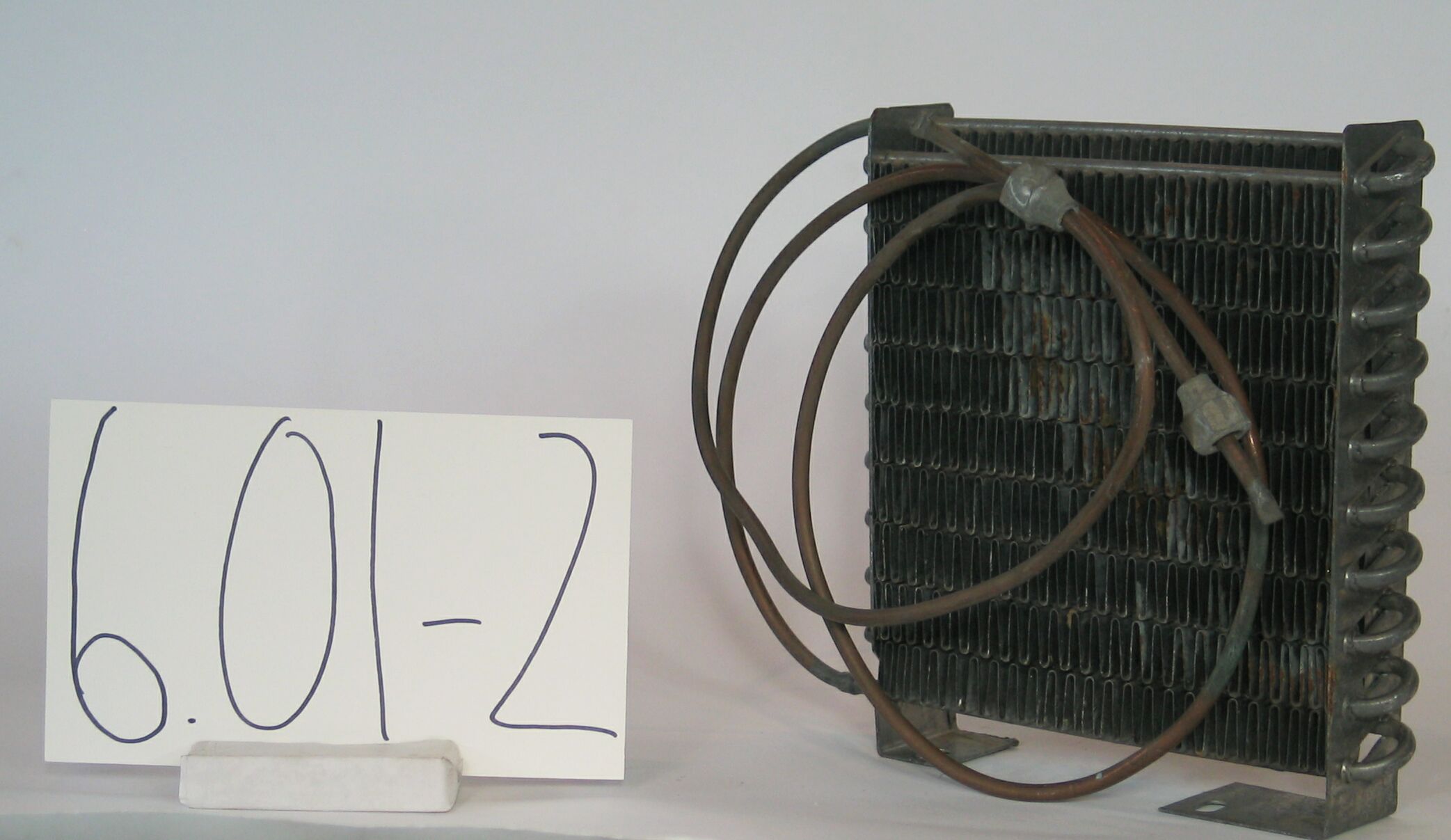

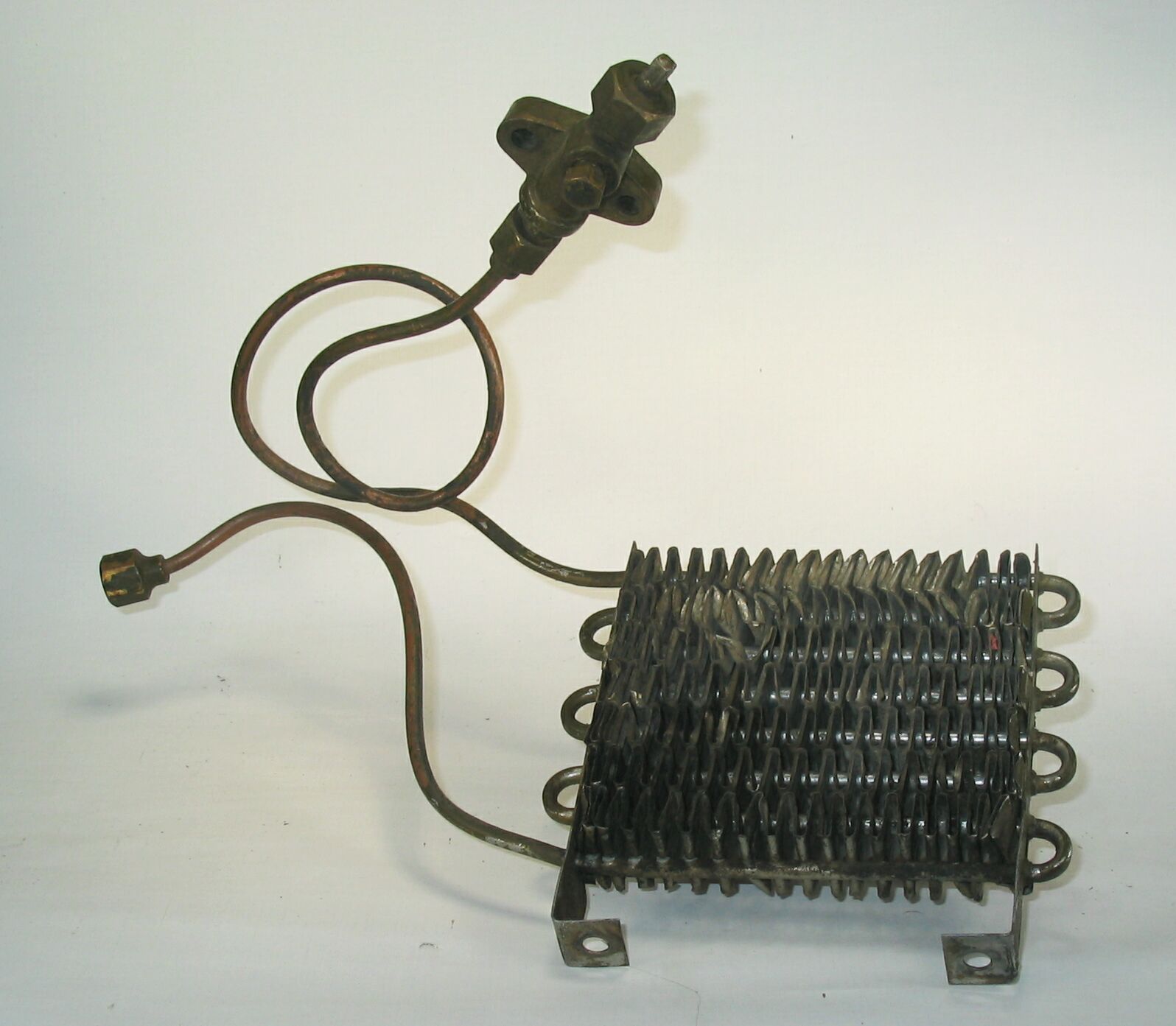

6.01-3: 1930's Air-Cooled Condensers

| HHCC Accession No. 2003.068 | HHCC Classification Code: 6.01-3 |

|---|

Description:

A set of three early, ‘original equipment manufacturer’ (OEM), fin and tube, air-cooled condensers of varying capacities, from the 1930’s, representing a range of Canadian OEM engineering and fabrication practices in ferrous and non ferrous materials (copper and aluminium) for use on refrigeration machines, with anhydrous sulphur dioxide refrigerant, 1930’s

Group:

6.01 Refrigerating and Air Conditioning Condensers and Receivers - Household

Make:

- Kelvinator

- Kelvinator

- Gilson

Manufacturer:

, Kelvinator of Canada, London Ontario Kelvinator of Canada, London Ontario Gilson Manufacturing Co. Quelph Ontario

Model:

Serial No.:

Size:

7x1x7’h 7x1.5x7’h 12x1.25x9’h

Weight:

2 lbs 4lbs. 5 lbs

Circa:

1930’s

Rating:

Exhibit, education, and research quality, demonstrating the options being explored in construction and engineering by Canadian OEM’s of forced air, refrigerant condensers, for small FHP refrigeration machines in Canada in the 1930’s

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Tined copper tube with pressed, aluminium, plate fin on tinned steel frame Tined copper tube with pressed serpentine fin on tinned steel frame Tined copper tube with pressed aluminium plate fin on tinned steel frame

Construction:

Material:

Special Features:

Accessories:

With brass, refrigerant, compressor discharge valves and copper tail pieces

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

Simple plate fins, engineered for a press fit on the condenser tube, as in examples 1 and 3 were relatively easily achieved. The serpentine, soldered fin construction in example 2 represented a 2 nd or 3 rd generation of fin engineering, with higher conductivity and thermal performance. The manufacturing process for producing the fins and soldering them in place was a mark of the increasing sophistication of Canadian manufacturing methods, in place by the end of the 1930’s.

As manufacturing methods evolved the Canadian industry would move to non-ferrous tube and fin construction [copper], see code no. 6.02-7, and eventually to non-corrosive refrigerants, including methyl chloride and Freon 12. But for now this construction genre remained as the state of the art, an important snapshot in time.

See also items 6.01-2, 6.01-3, 6.02-7, 6.02-8, together they profile the evolution of the tube and fin, air-cooled condenser for FHP refrigeration machines in Canada

Industrial Significance:

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection