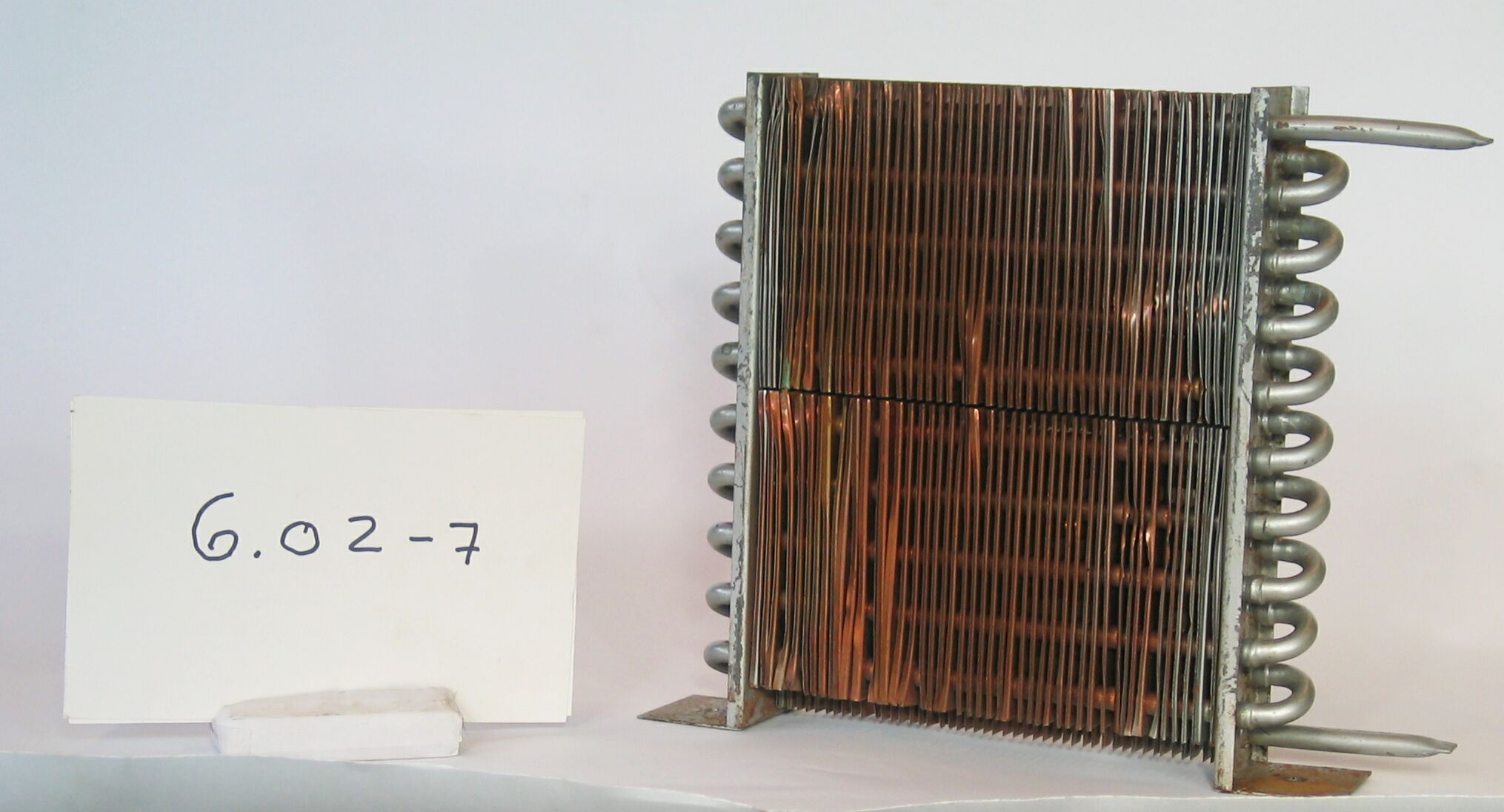

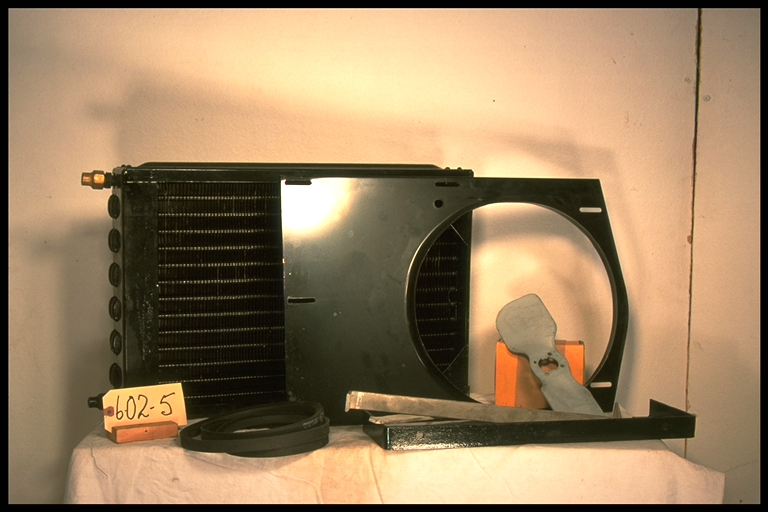

6.02-6: Frigidaire 1941 Air-Cooled Condenser

| HHCC Accession No. 2003.065 | HHCC Classification Code: 6.02-6 |

|---|

Description:

A ‘modernization’ kit, by Frigidaire for replacing the copper tube, coil, static air condensers on their Model K, enclosed, cabinet model, refrigeration machine [See 1tem 051]with a forces air, fin and tube, radiator style, high efficiency condenser. Constructed of heavily tinned copper tubing, for use with corrosive, noxious anhydrous SO2, it used heavy steel fins, coated with gloss black enamel, a truly remarkable piece of re-engineering for the ‘after market’ of the 1940’, Frigidaire, 1941

Group:

6.02 Refrigerating and Air Conditioning Condensers and Receivers - Commercial

Make:

Frigidaire

Manufacturer:

Frigidaire Corporation, Dayton Ohio

Model:

Frigidaire Unit Package No. EM113771

Serial No.:

Size:

22x6x16’h

Weight:

35 lbs.

Circa:

1941

Rating:

Exhibit, education, and research quality, demonstrating the construction and engineering design practices of the times, as well as the commitment of the refrigeration industry to servicing the ‘after market’ with product modifications and equipment upgrades in a period of rapid technological change

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

With original installation instructions

Type and Design:

Construction:

Kit parts include fan blade, V belt, stabilising brackets and angle iron base

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

A remarkable snap shot in time, demonstrating manufacturing and engineering practices for operation in the corrosive atmosphere of anhydrous sulphur dioxide, including the use of costly, heavy, tinned, coated copper and an enamelled steel case and fins. The enamelling of fins would represent a significant bow to the issue of corrosion resistance at the cost of lower heat transfer.

The streamlined air shroud is an indication of the increasingly engineering sophistication in airflow design, as well as manufacturing methods.

The high gloss sprayed finish is also a significant marker of the times, in contrast to the crude machine black finishes of items 061, 062, and 063, for example. Duco enamels and the spray techniques for applying them industrially was a significant technological advancement of the period.

Industrial Significance:

Of significance also is the commitment of Frigidaire to the continued use of anhydrous sulphur dioxide well into the 1940’s. It was a period in which much of the industry looked to system upgrades adapting then for use with the new chlorinated hydrocarbon refrigerants, non-corrosive and non-noxious.

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection