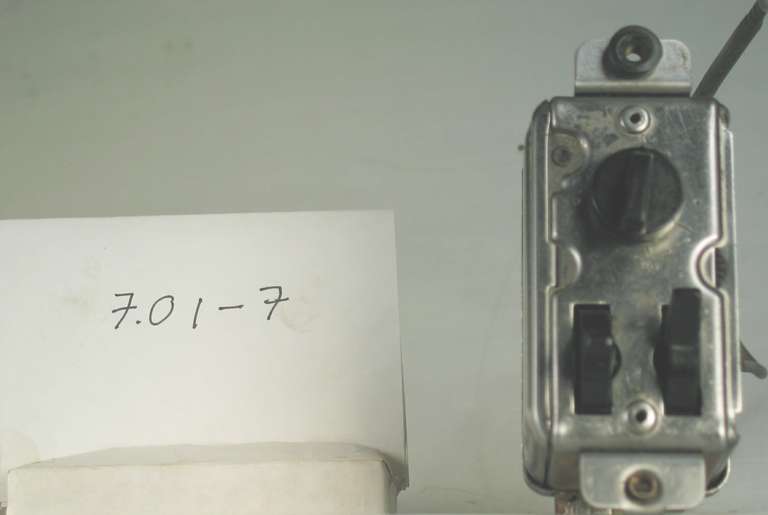

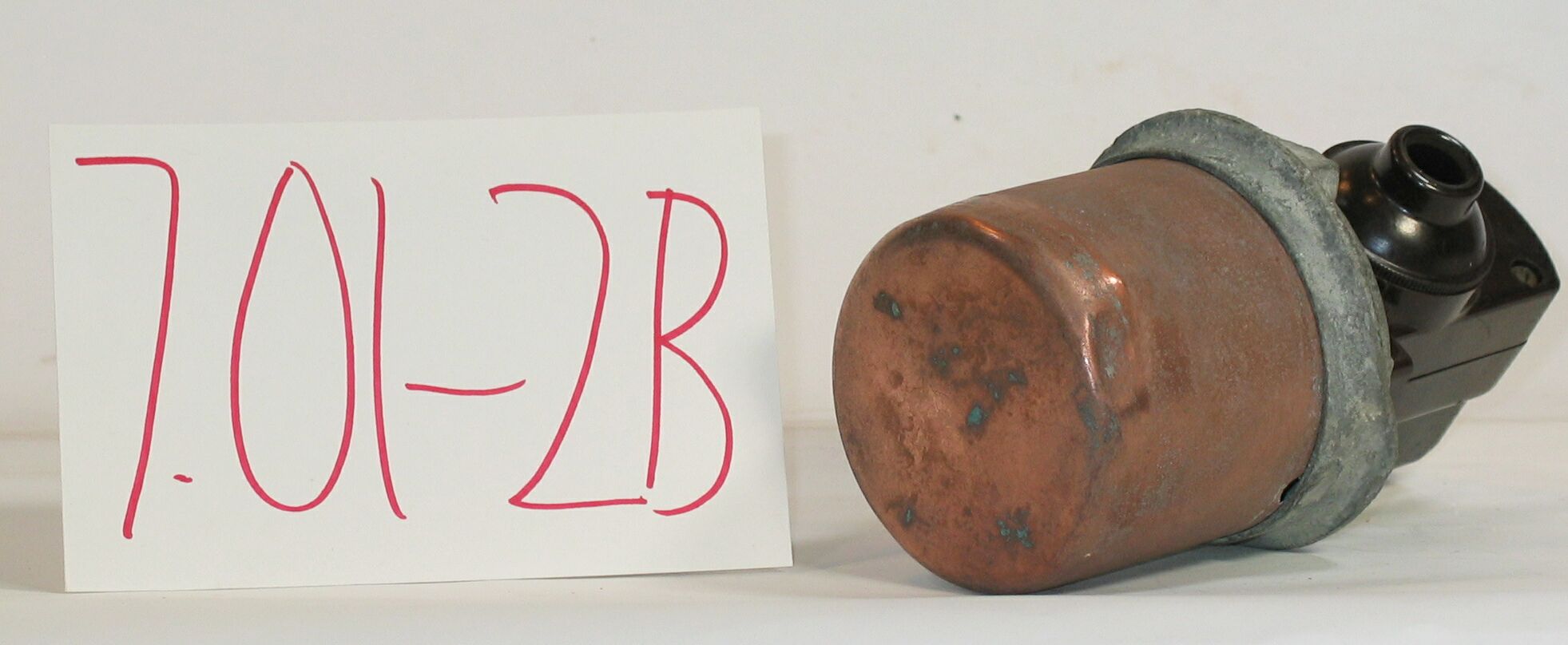

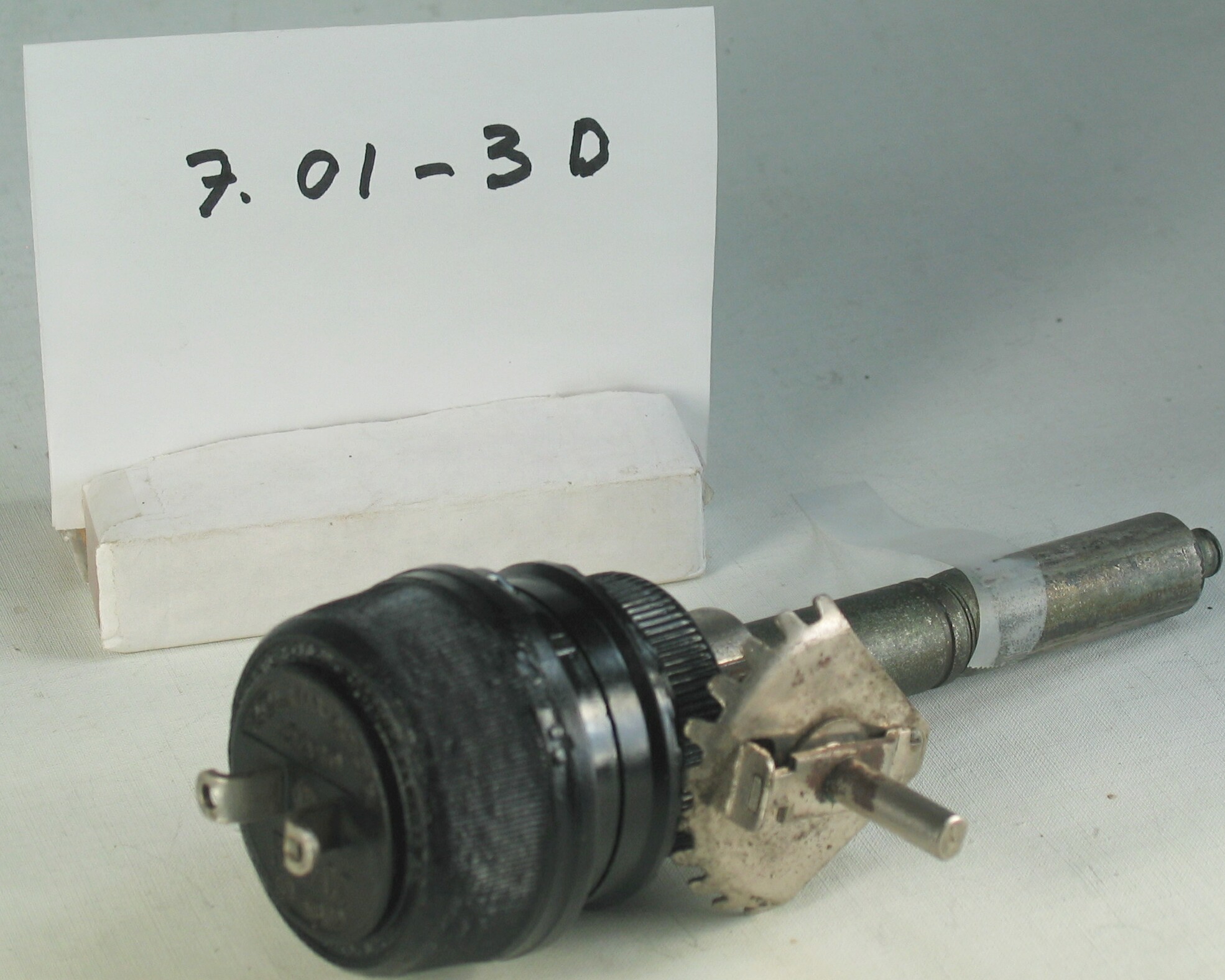

7.01-7: Ranco 1945 Automatic Temperature Control

| HHCC Accession No. 2006.022 | HHCC Classification Code: 7.01-7 |

|---|

Description:

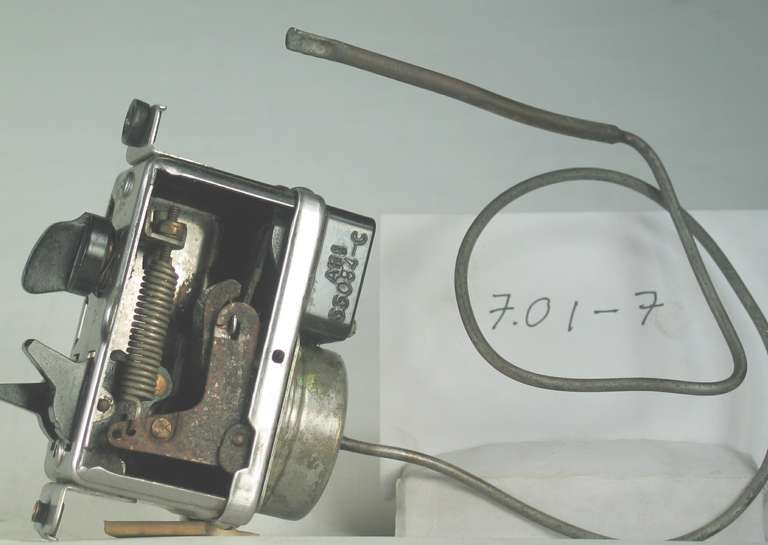

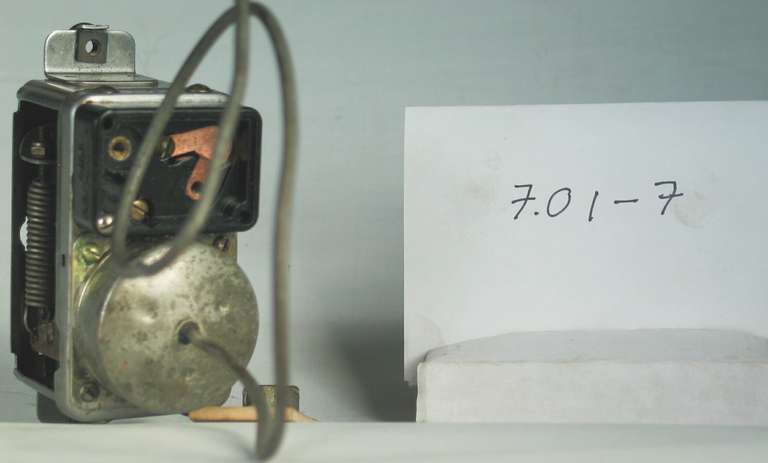

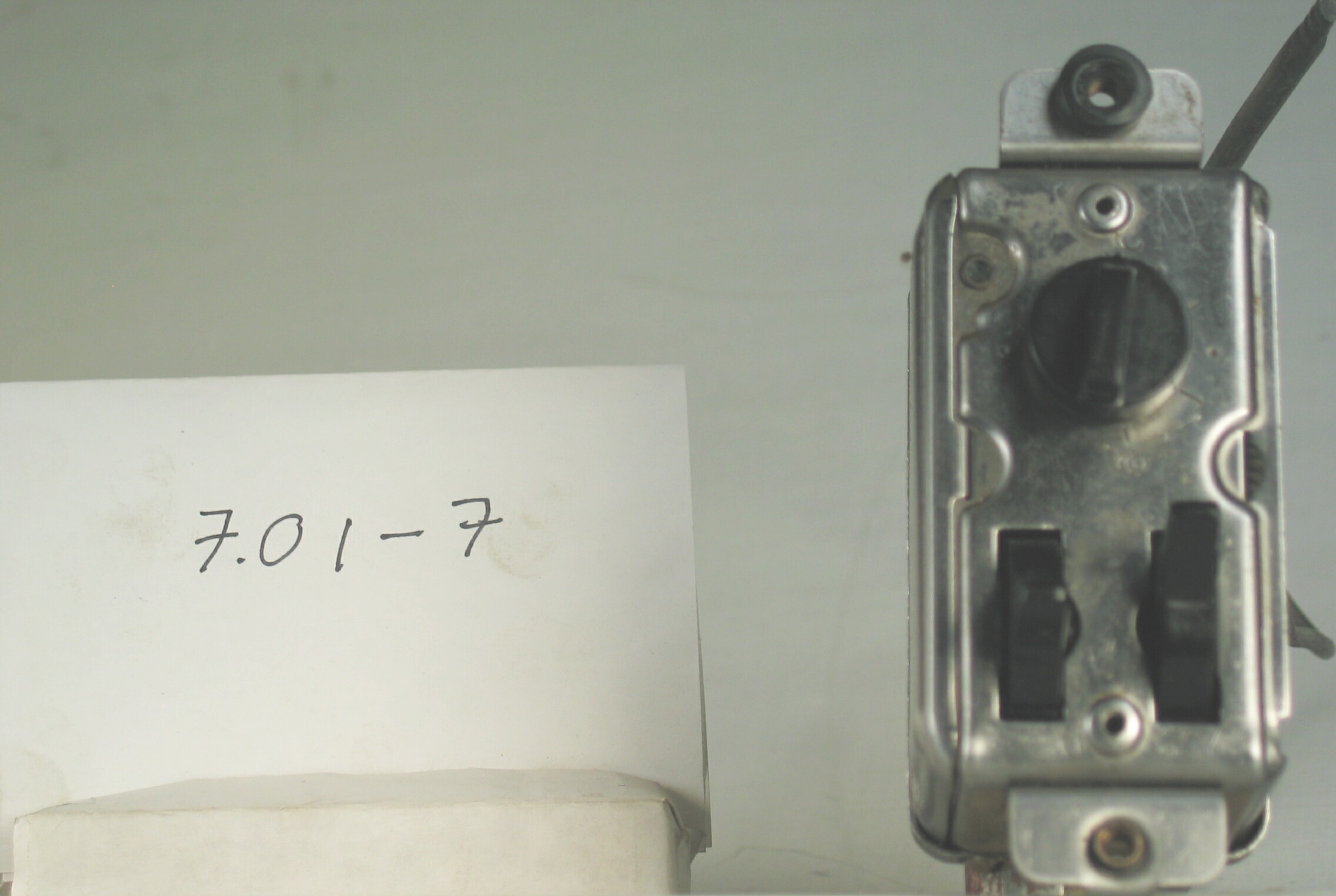

An hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing, equipped with manual reset, electric motor overload protection, and a semi-automatic defrost feature, enclosed in new compact stainless steel case, Ranco, Type KR, circa 1945

One of a series of early, hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing ‘ the preferred sensing technology of the mid 20th century. [See items ID # 142- 151]. The genre would give way by the end of the century to electronic sensing methods.

Group:

7.01 Refrigerating and Air Conditioning Pressure and Temperature Controls - Household

Make:

Ranco

Manufacturer:

ARCB Co., Columbus Ohio

Model:

Type KR

Serial No.:

Body markings AH1; 55084-C

Size:

2.5 in. long plus capillary line x 1.5 x 4 in. high

Weight:

9 oz

Circa:

1945

Rating:

Exhibit, education, research, and demonstration quality illustrating a significant milestone in the evolution of extended capillary tube technology through a myriad engineering design developments and applications.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Extended capillary tube sensing Designed for commercial and household applications up to ‘ HP

Construction:

Gone was the costly Bakelite case to be replaced by a simple, cost saving stamped and formed case in stainless steel sheet stock

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

The series [see items ID # 142- 151] profiles the evolution of extended capillary tube technology through a myriad engineering design developments and applications. It was a period driven by, and responding to, a new often shameless, marketing hyperbola. For the industry would take full advantage of knowledge from the newly found thermal and fluid flow sciences of the times, as well as of the new materials technology and manufacturing methods of the immediate pre-W.W.II years.

The industry was clearly out to create ever-increasing consumer interest and expectations for a user friendly, fully automated, self-regulating, affordable, mechanically driven cabinet refrigerators for the Canadian home. It was ‘an automatic refrigerator in every kitchen’ following the marketing pattern set by the automobile industry for ‘an automobile in every garage’, that was the call of the captains of the household refrigeration industry. The perfection of a reliable, affordable, and user friendly, automatic temperature control was critical to the success of this business venture.

The Type KR series while found on household cabinet refrigerators was most often found on small unitary commercial applications, such as beverage coolers, ice cream cabinets, water coolers, and reach in cabinet refrigerators.

The control with its corroded mechanism illustrates a common cause of failure, in small unitary applications, subject to condensation and water leaks.

Industrial Significance:

see above

Socio-economic Significance:

see above

Socio-cultural Significance:

- see above

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Ranco Service Manual #1058, November 1960, P.282

Notes:

- Side panel, switch cover and thermal overload heater not included