7.02-9: Honeywell 1945 Automatic Temperature Control

| HHCC Accession No. 2006.040 | HHCC Classification Code: 7.02-9 |

|---|

Description:

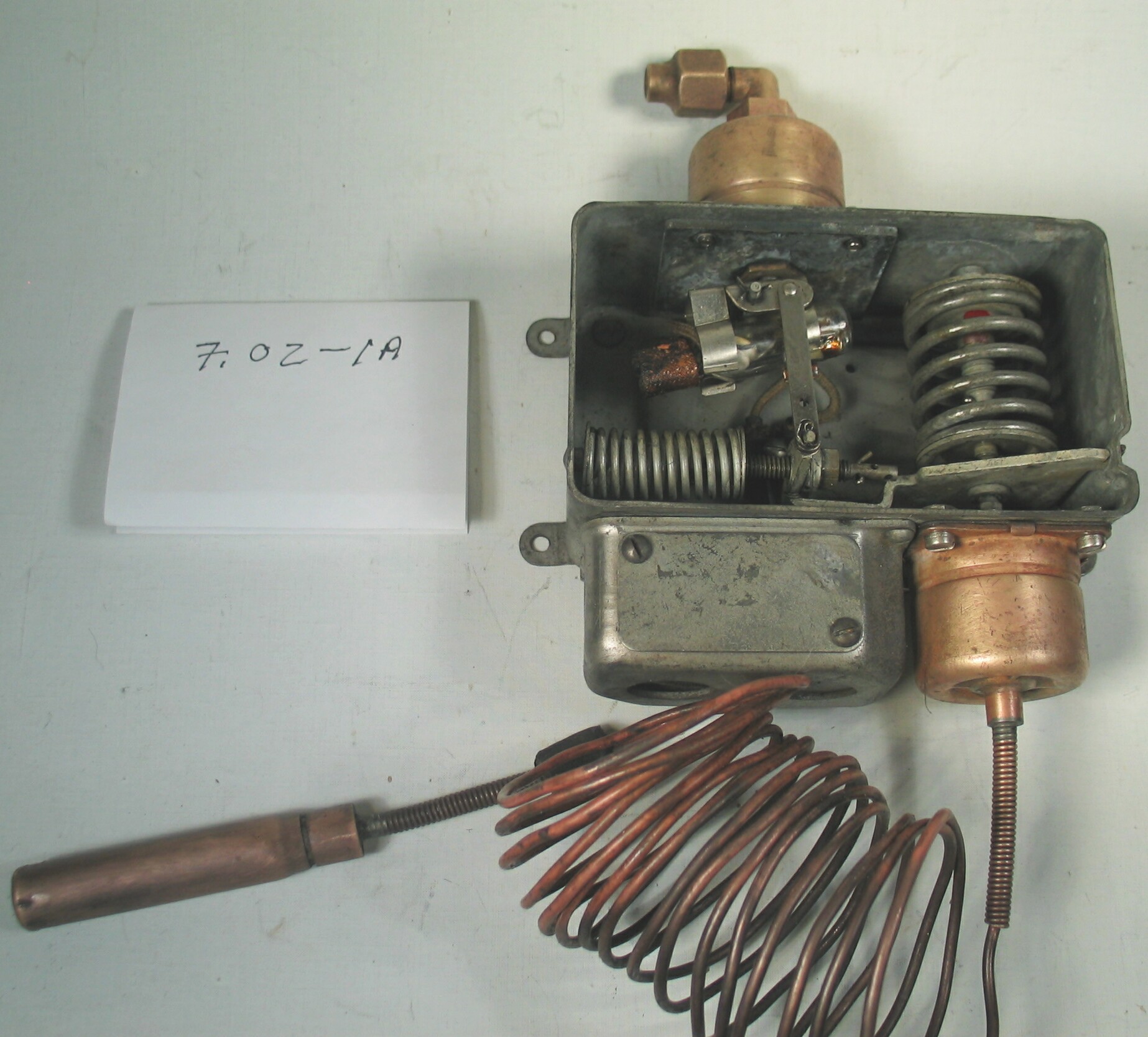

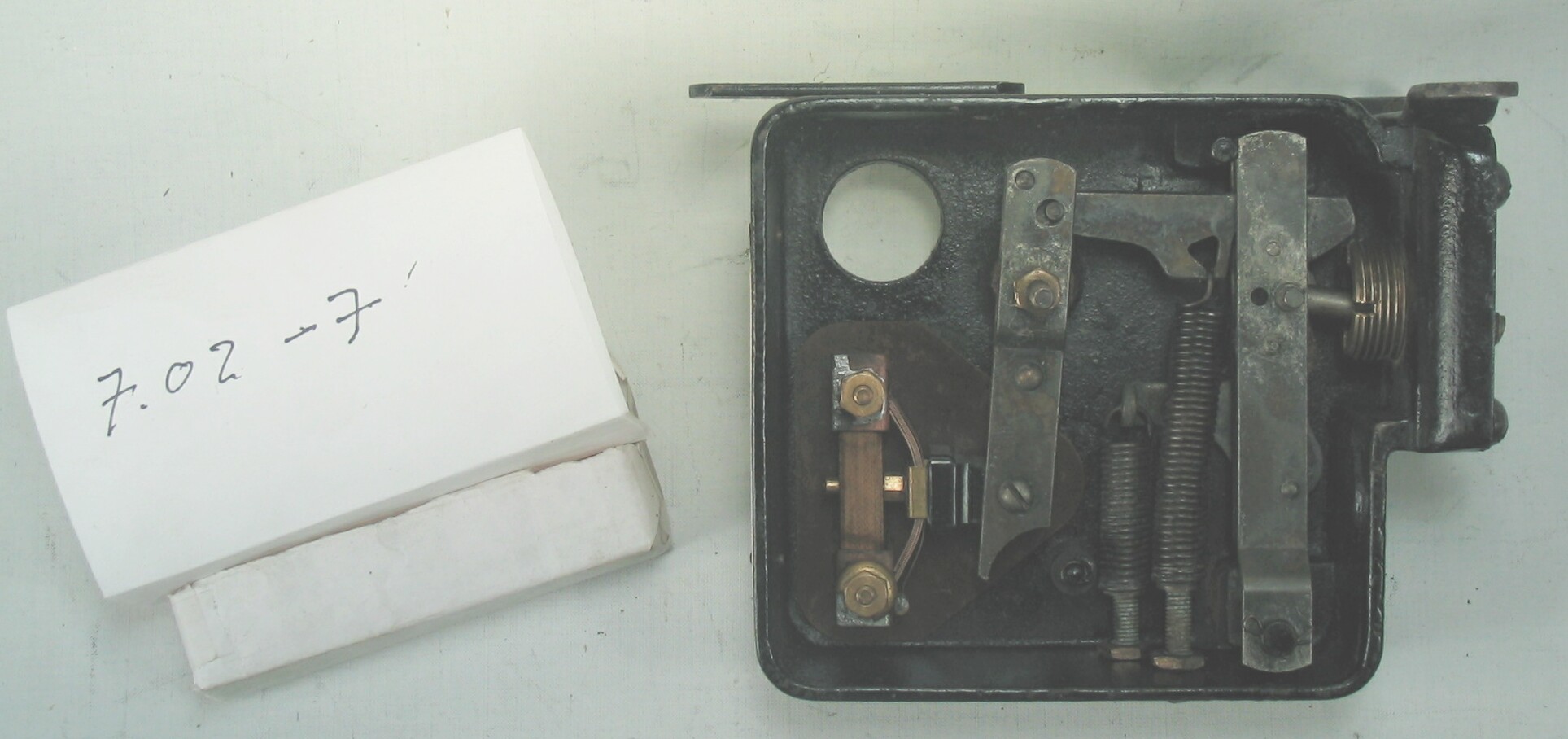

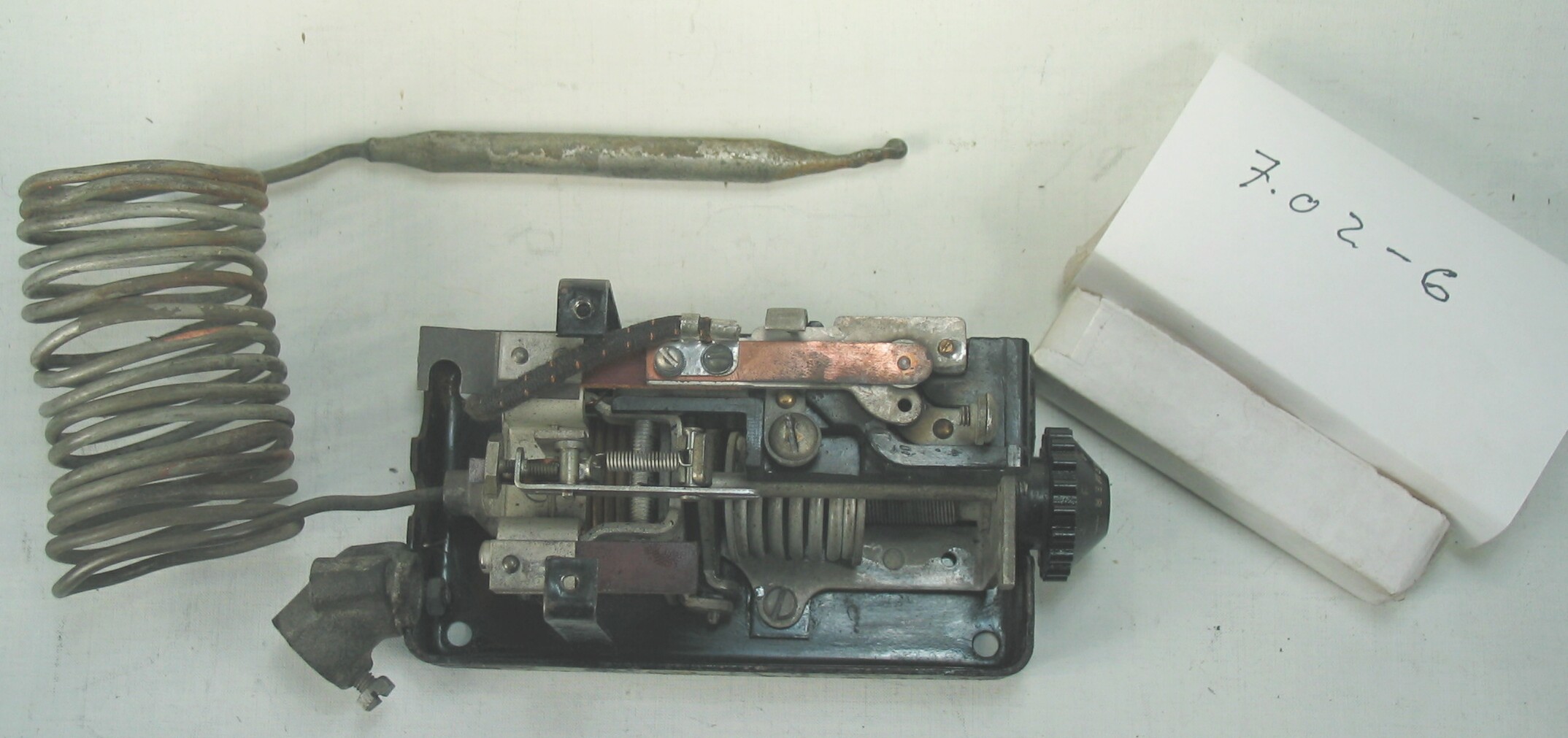

Automatic, hydraulic bellows actuated, dual function, high pressure and low-side temperature control with extended capillary tube, for commercial and industrial refrigeration equipment applications, equipped with fully adjustable, user friendly range and differential settings, and tilting mercury bulb switching, in attractive, streamlined heavy, plated steel enclosure, now telling the many stories of natural use on a farm milk cooler in York Region, Minneapolis-Honeywell, Circa 1945.

Group:

7.02 Refrigerating and Air Conditioning Pressure and Temperature Controls - Commercial

Make:

Minneapolis-Honeywell

Manufacturer:

Minneapolis-Honeywell Regulator Co. Minneapolis, Min,

Model:

Type L413-1

Serial No.:

CS number 373-293

Size:

7 x 3 x 7 in h, plus capillary line

Weight:

3 lbs.

Circa:

1945

Rating:

Exhibit, education, and research quality, illustrating the engineering and construction idiom of the mid 20th century, multiple functions and applications - by arguably the leading manufacturer of electric and pneumatic control devices of the period.

Patent Date/Number:

Eight US patents listed 1598874 to 1827072 [1926 to 1931] Canadian Patent 255926 [1925]

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This particular control was used on a farm milk cooler installation in York County [York Region] north of Toronto, through the 1940’s and into the 50’s. Its unique patina tells many stories of farm life and practice in the storage and processing of milk on a typical Ontario farm of the period

It was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

The control carries a hand written tag in Howard Olivers hand, ‘Erratic Operation’

Type and Design:

Hydraulic bellows actuated Tilting mercury bulb switching Widely adjustable range and differential settings Dual hydraulic bellows for pressure and temperature sensing

Construction:

Material:

Special Features:

Attractive, simple elegant styling with plated steel, bright enclosure, long radius streamlined corners and decorated nameplate cover in green. A mercury bulb controller, with precision mechanism, it includes calibrated scales for cut-out and differential field adjustment and out-board replaceable and interchangeable bellows. With miniature, built-in pendulum to help ensure plumb mounting needed for the precise operation of the mercury bulb at designated control point. Once beautifully engineered, it is enclosed in stream lined, formed steel, bright plated enclosure with, full front, access cover: but now stained and spotted with white paint telling the stories of many years of use on Ontario farm near Aurora, on a typical, early, mechanically refrigerated, water bath milk cooler

Accessories:

Capacities:

Performance Characteristics:

Temp +10 to + 50 deg. F Pres. 150 to 180 psi

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

Representative of leading practice in the engineering of sophisticated state of the art, dual function, automated refrigerant high pressure cut-out and low-side temperature controllers of the mid 20th century. Built on a platform that was readily adaptable to a wide range of functions and applications it represented a significant advance in the field, enabling an ever widening range of functionality, and equipment manufacture’s needs. [See also ID # 163, 7.02-8] New also for the period was the attention given by leading control manufacturers to product support. The L series, in its many variations, is well documented in company catalogues and in field instruction sheets, variously dated through the latter 1940’s and 50’s. The control was made in a number of versions for industrial, as well as commercial refrigeration applications, including farm milk coolers, refrigerated display cases, walk-in coolers and freezer cabinets.

Industrial Significance:

The Minneapolis-Honeywell L control series represented well the mid-century control technology of the times, enabling the development of a vast range of new refrigeration applications by the Canadian refrigeration industry.

Socio-economic Significance:

Socio-cultural Significance:

The Canadian public, for their part, would be aware of an explosion of new refrigerated facilities, many of them in the form of self-served display cases to be seen in food stores, butcher- shops and bakeries across the country. What had been enabled by a new generation of controllers, in concert with a new generation of refrigeration machinery [condensing units], innovative, evaporator engineering employing high efficiency designs in aluminium, as well as by new expansion valve technology [See HHCC Series 3.02 Artifacts ] was period of phenomenal growth in the Canadian refrigeration industry. It was a period that would see an irreversible change the eating and food preparation, storage, merchandizing, as well as food shopping habits of all Canadians.

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Honeywell ‘Catalog’ of Automatic Controls, Number 59, Toronto Ontario, undated [likely 1959], P88-89