12.05-4: Fess 1940 Fuel Oil Atomizing Firing Head

| HHCC Accession No. 2006.138 | HHCC Classification Code: 12.05-4 |

|---|

Description:

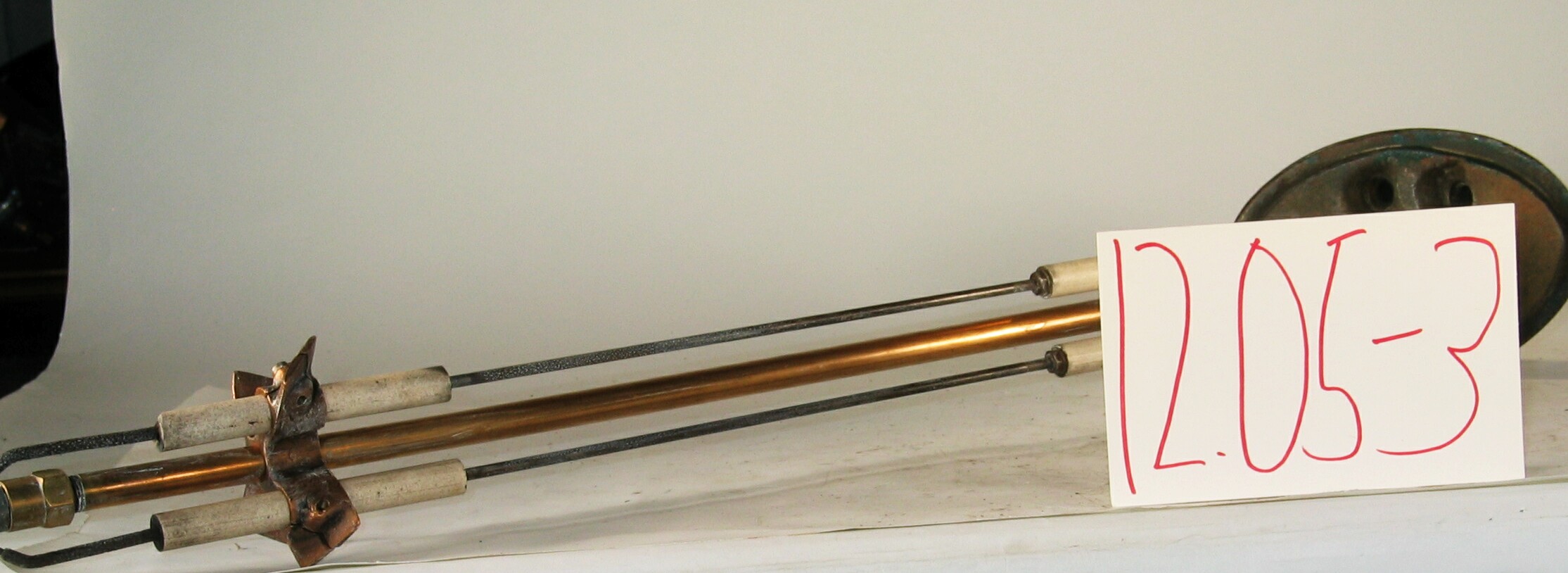

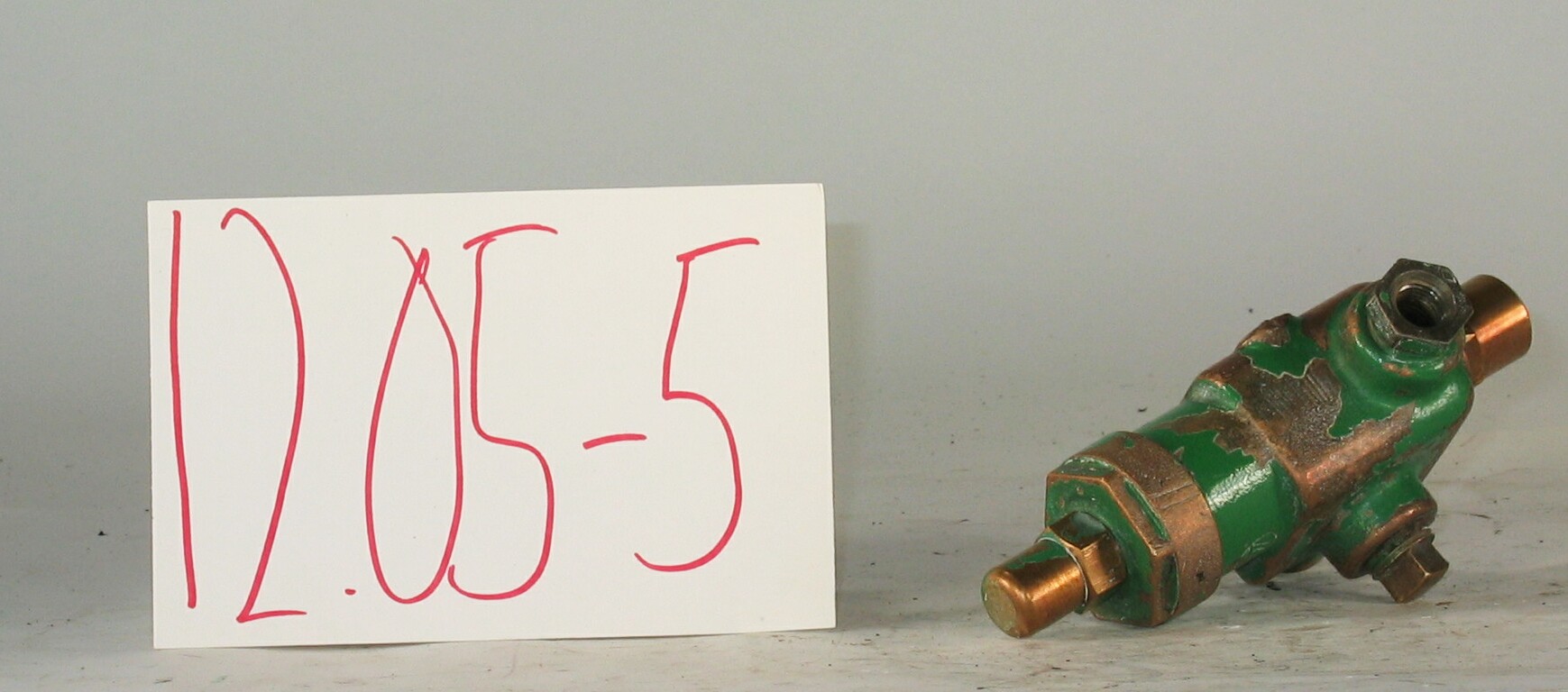

A field modified high pressure fuel oil atomizing firing head by Fess Oil Burners, Toronto, an acknowledged early pioneer in oil burner engineering and manufacture in Canada; with classic black/green enamelled finish, long-reach, 3/8 inch, brass, oil delivery tube, inlet oil filter and oil-flow shut-off valve, and modified with the addition of a Honeywell dripples, automatic, oil pressure control, check valve, Fess, Model J31, Circa 1940. [see also ID#261]

Group:

12.05 Pressure Atomizing Oil Burner Equipment and Systems - Firing Assemblies

Make:

Fess

Manufacturer:

Fess Oil Burners Canada, Toronto

Model:

Model J-31

Serial No.:

Size:

3 inch dia x 8 inch long plus pipe oulet connection

Weight:

5 lbs.

Circa:

1940

Rating:

Exhibit, education, and research quality, illustrating the engineering, design and construction of high pressure, oil atomizing firing assemblies, a basic configuration which would sustain much of the industry throughout the balance of the 20th century.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Used on an automatic oil heating system, in an estate home, in York County [York Region] north of Toronto

Type and Design:

High voltage electric porcelain ignition electrodes, Brass air turbulator Stainless steel pressure atomizing nozzle, Monarch, .85 gpm, 80 deg. R. Cast iron end plate in Fess Oil Burner, classic black/green finish, Assembled on extended, long reach, 3/8 inch IPS brass oil delivery tube Brass body, inlet oil filter and oil flow shut- off valve in classic Fess Oil Burner black/green Original high tension ignition cables Field modified with the addition of a Honeywell Type V5000A2X, dripples oil flow check valve, 85 psi.

Construction:

Material:

Special Features:

Original high tension ignition cables

Accessories:

Honeywell Type V5000A2X, dripples oil flow check valve, 85 psi.

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

A marker of the times in the evolution of automatic oil heating for the Canadian home, this 24 inch, long-reach firing assembly, typical of the period, was designed for ‘conversion’ installation. Such installations were typically found in gravity style, home warm air heating furnace installations in the early years of the 20th century. Here coal grates would be removed, and oil burner refractory would be hand built in its place and a firing head would be inserted, See ID# 243, 244,245. This firing head, typical of the period, slides into a large (4” to 5”) fire tube [gun]. It delivers oil at up to 100 psi. to an oil atomizing spray nozzle through a 3/8” brass, oil delivery tube. Turbulated air under pressure is forced through an air cone [see ID# 64 and 265] where it is mixed with the atomized oil spray and ignited by an electrically generated spark [See ID# 255 and 256] jumping between two carefully positioned electrodes. High tension insulated cables carry the electrical current to the electrodes, through fragile, porcelain electrical insulators. The oil atomizing nozzle, first developed in the 1920’s would be a marvel of its times, in product engineering and design, as well as in mass production manufacture. Designed to produce a variety of air patterns, with different combustion characteristics, it would survive relatively unchanged through to the 21st century. This firing assembly, modified 10 years or so after first installation, suggests something of the long ‘shelf life’ of the basic technology. A performance characteristic of such firing assemblies was the tendency to eject oil into the firebox at below the specified design pressure, 85 to 100 psi. The result was poor combustion and a smoky, smelly fire. Usually caused by a fuel pump failing to open at the proper pressure, the dripples valve would provide a quick fix, a less expensive alternative to pump repair or replacement.

Industrial Significance:

This high pressure, high voltage, fuel oil atomizing firing head by Fess Oil Burners, Toronto, stands as a marker of the earliest pioneering work of a Canadian company in the engineering and manufacture of automatic heating equipment designed for the Canadian home. This basic firing head configuration would meet many of the needs of the market-place, and satisfy minimal safety requirements through to the end of the 20th century During this period, however, engineering applications progressed well beyond the ‘conversion’ market, to smaller, more efficient, unitary, packaged automatic oil heating equipment, for both warm air and hot water [hydronic]. As a result firing assemblies would become much more compact and sophisticated in design. Yet, the basic engineering design trend had been set by the early 1930’s. Fragile and often temperamental, as it was, firing assemblies of this essential configuration, modified and customized for different applications, would remain the standard for high pressure atomizing oil burners to the end of the 20th century.

Socio-economic Significance:

In the 1920’s and 30’s manufacturers had a selling job to do, and knew it. They took every opportunity to demonstrate the safety, quality, strength, durability and reliability of their home heating equipment. Safety was a core concern in the embryonic and early development years of the field. Consumers were rightly concerned about that 3000 deg, ball of fire in the family furnace, starting and stopping, often with a bang and a roar and typically with a distinct smell of raw fuel oil and its products of combustion. And all of this would happen, automatically, at all hours of the day and night without the touch of a human hand. [See also group items 12.08 automatic combustion, safety controls]. On the subject of consumer risk assessment and related risk taking behaviour, Jonathan Rees recently notes that anthropological studies show that cultural factors play a major role ‘ not surprisingly. As automated technology and machines moved into the home with ever-greater frequency [automatic oil heating and refrigeration equipment], consumers saw the potential danger of unbridled technology up close, maybe for the first time. Insurance companies, who earlier might have written off incidences of property damage and personal injury as mere lapses in good safety practice or as ‘acts of God’, became much less willing to do so.

At the same time government agencies, sensing potential risks of unattended technology, to public health and safety, would be increasingly drawn into the testing and regulatory field. As all this was happening, engineers and manufacturers were, themselves, becoming increasingly circumspect about the dangers of the automated mechanisms they offered for public consumption, and the moral, legal and financial burdens to be born - see Note No 1. The preconditions had been set for the progressive development of consumer protection legislation and related requirements, which would continue to snow-ball well into the 21st century. Consumer instructions and warnings about this and that aspect of system operation and possible performance malfunction, would soon be an essential part of the homeowners operating manual.

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Conservation and preservation work remains to be done.

Bibliographic References:

Notes:

See ‘I Did Not Know’Any Danger Was Attached, Safety Consciousness in the Early American Ice and Refrigeration Industries’, Jonathan Rees, Technology and Culture, Vol. 46, Number 3, July 2005, pp 541 to 556.