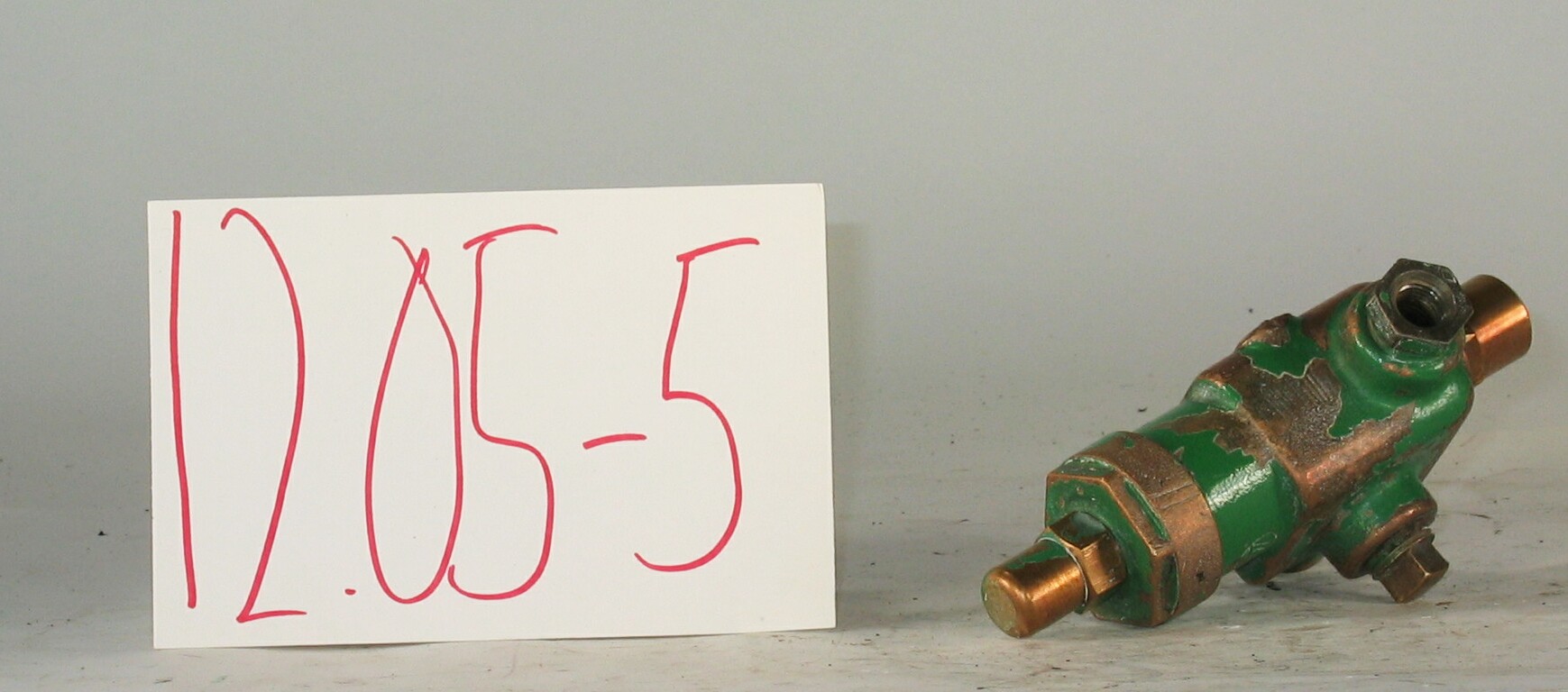

12.05-6: 1948 Air Cone for Atomizing Oil Burner

| HHCC Accession No. 2006.140 | HHCC Classification Code: 12.05-6 |

|---|

Description:

An air cone for a high pressure, atomizing oil burner, designed with convex nose and 8 turbulator blades. Unobtrusive and elemental in appearance and seemingly of little consequence, it would, none-the-less, prove to be a critical component in oil burner performance in its time, helping to ensure quiet, efficient, smoke free combustion. Blued and heavily corroded as a result of use in a typical 3000 deg. combustion chamber, unknown manufacturer, Circa 1948 [see also ID#265]

Group:

12.05 Pressure Atomizing Oil Burner Equipment and Systems - Firing Assemblies

Make:

Unknown

Manufacturer:

Unknown

Model:

Unknown

Serial No.:

Size:

5 inch dia x 1.5 inches

Weight:

1.3 lbs.

Circa:

1948

Rating:

Exhibit, education, and research quality, exemplifies the range of unobtrusive, seemly elemental component parts on which the performance of automatic oil burners would be desperately depend in the middle years of the 20th century

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Used on an automatic oil heating system, in an estate home, in York County [York Region] north of Toronto

Type and Design:

Cast iron Equipped with machined collar for light pressed fit on oil burner firing tube Hole for screw attachment Eight diagonally cast turbulator blades Convex, domed face Blued and heavily corroded showing the effect of normal use in high temperature 3000 deg, combustion chamber

Construction:

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

The simple, crude air cone, a piece of sand moulded and machined cast iron, would come to represent much of the challenge faced in squeezing acceptable levels of reliable performance out of the high pressure atomizing oil burner, given the state of that technology in the early and mid 20th century. In this period, experiments in refractory, air cone, air turbulator, nozzle, electrode and oil pump design would be endless, in an attempt to optimize a technology which refused to be optimized, until significant redesign and re-configuring of the high pressure atomizing burner took place in the latter years of the century. [See Reference 1]

This seemingly simple, elemental device stands as a reminder of the system of often crudely fashioned, empirically derived, interrelated and mutually supporting component parts on which the safe, reliable and efficient operation of automatic oil heating for the Canadian home would depend in the mid 20th century.

Industrial Significance:

Many variations in air cone design are to be found, reflecting the practice of the period. Each manufacturer would experiment to find the configuration best suited to his equipment’s performance ‘ see ID#265

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

See ‘Service on Pressure Burners, Details on Handling Oil Pumping Troubles, J. W. Schulz, Better Oil Heating, A Service Guide, Fueloil and Oil Heating, N.Y., 1959