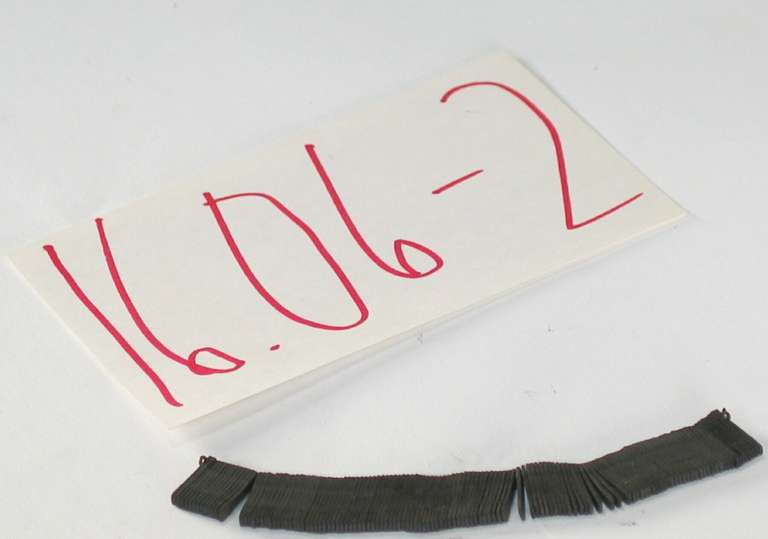

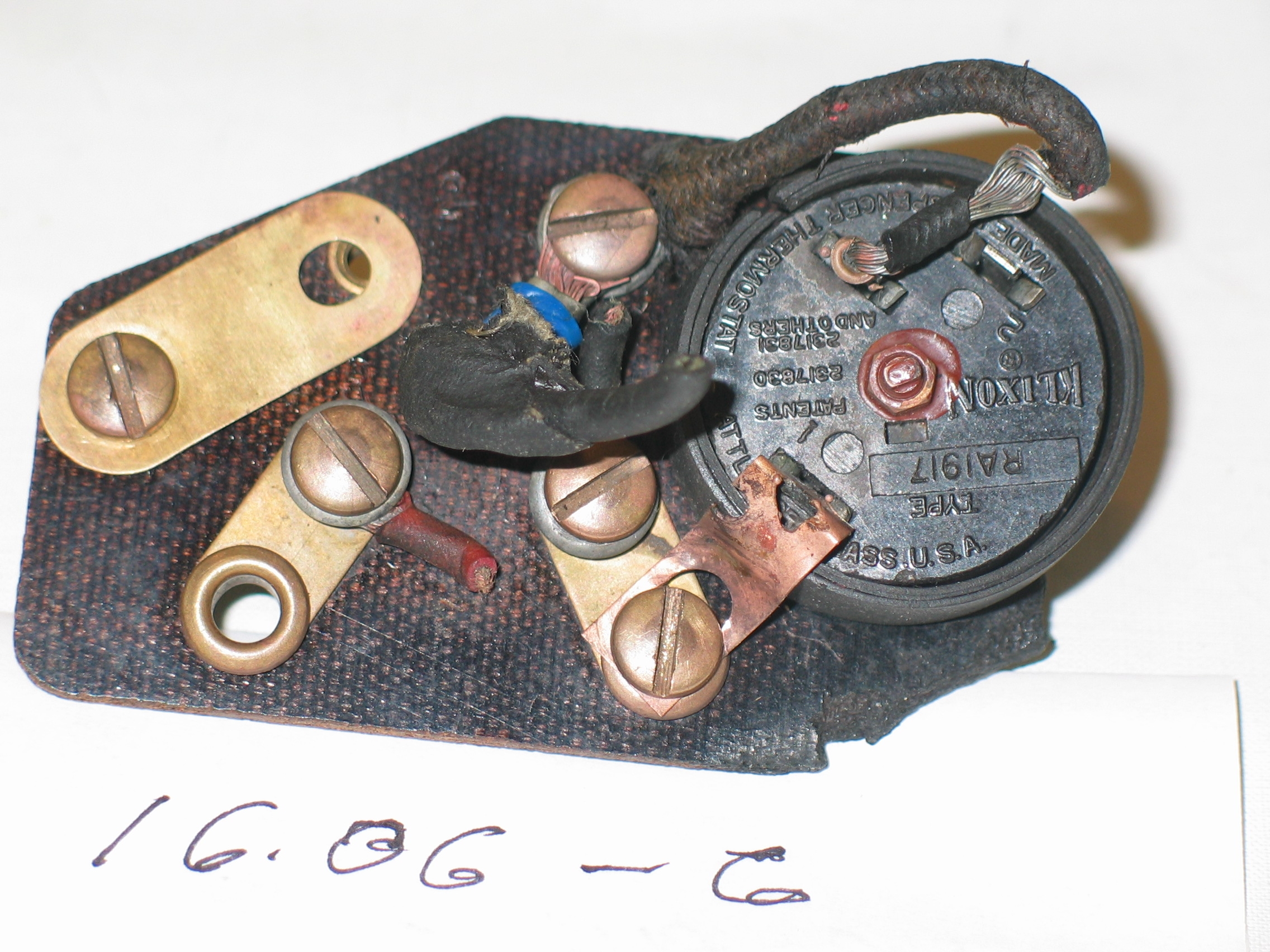

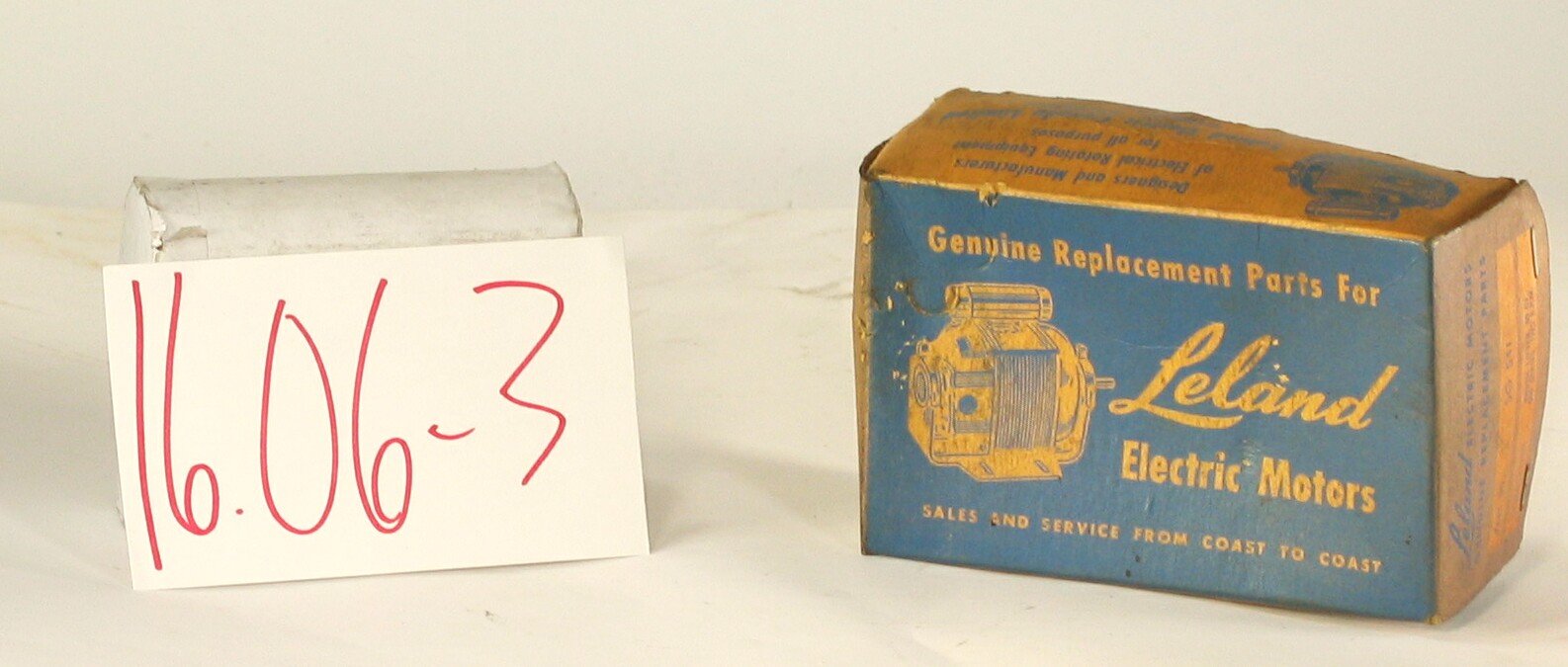

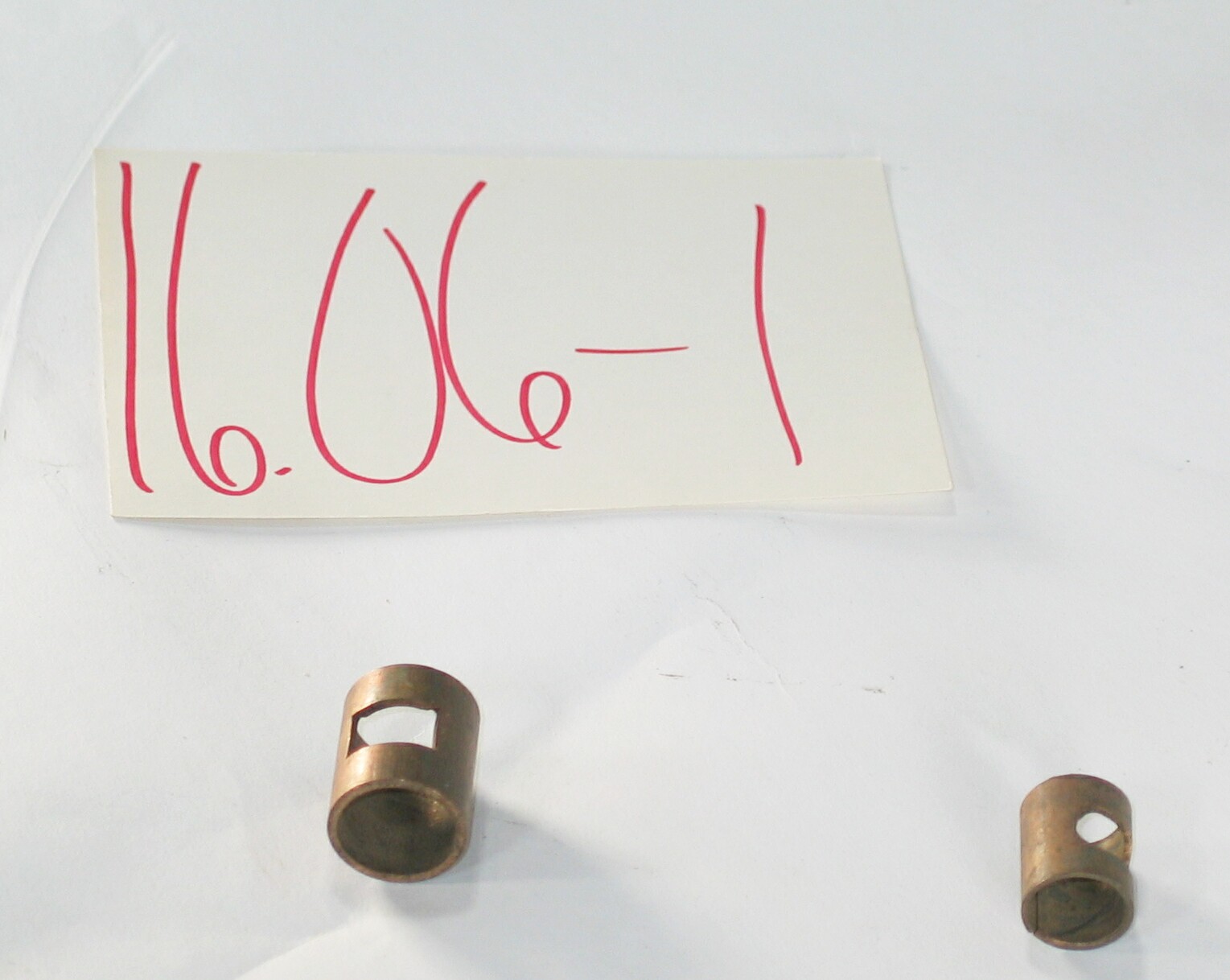

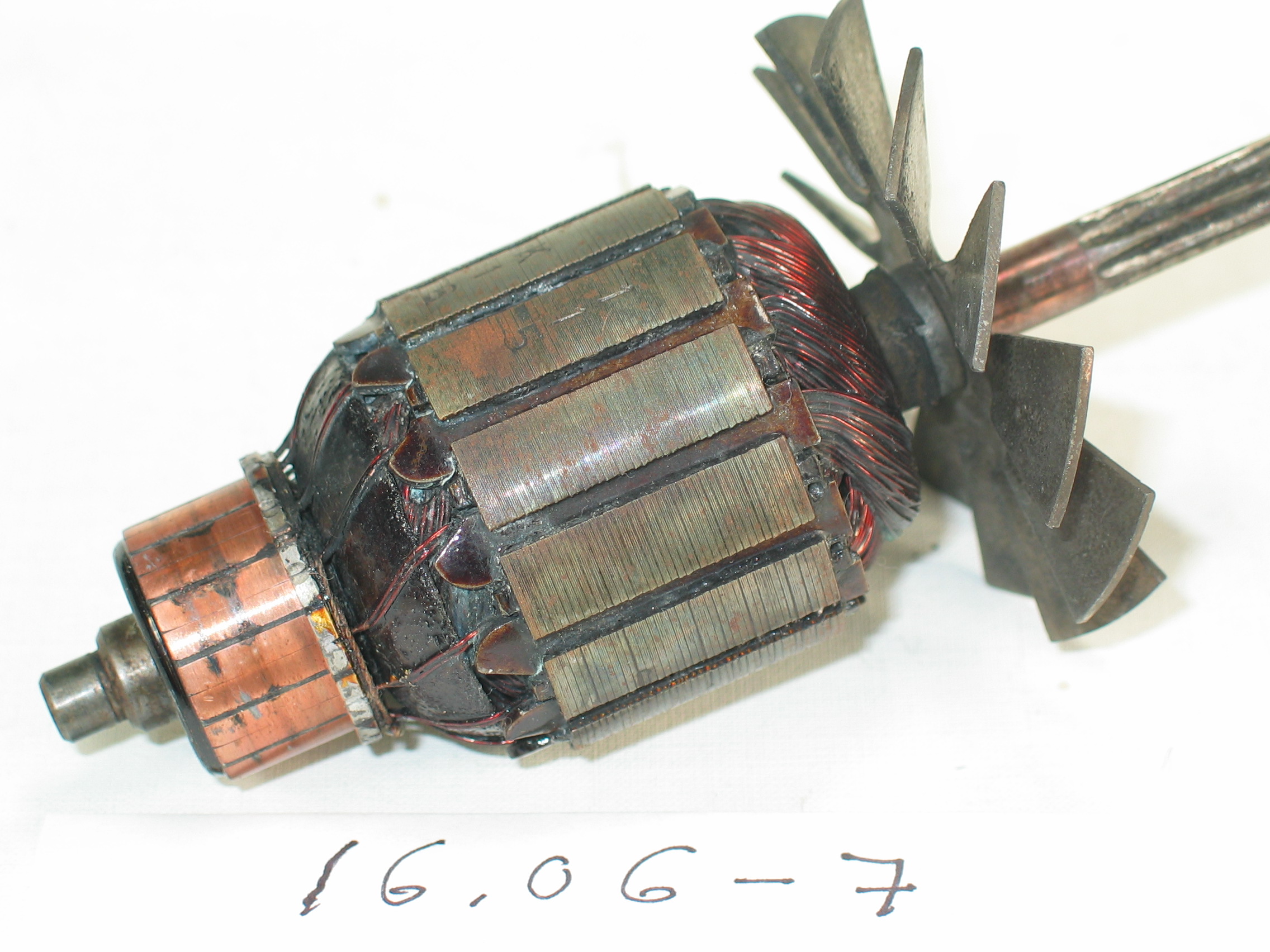

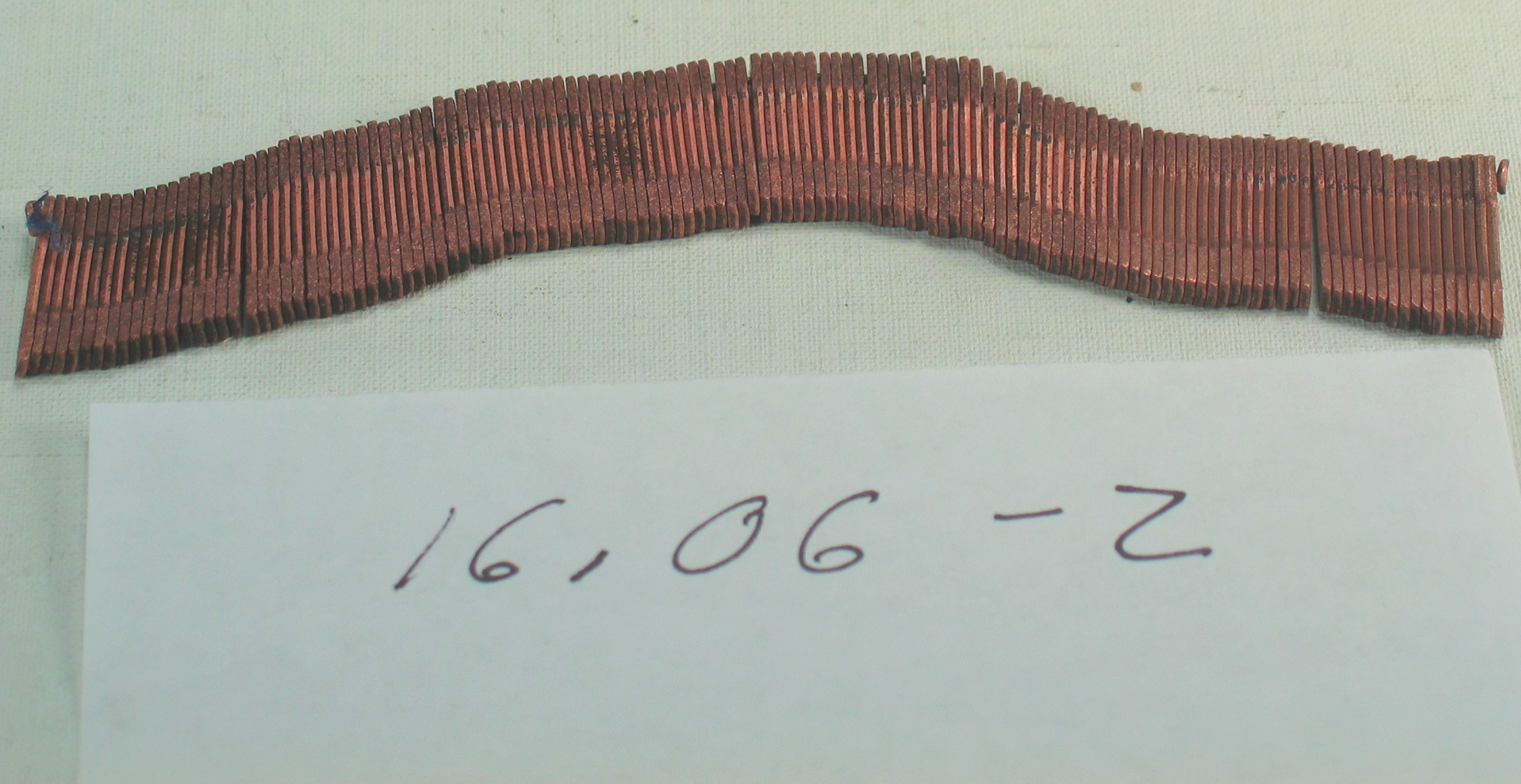

16.06-2: Wagner 1932 Short Circuiting Conversion Ring

| HHCC Accession No. 2006.203 | HHCC Classification Code: 16.06-2 |

|---|

Description:

A rare view of an early 1930’s, short circuiting ring [necklace], constructed of copper, stamped and formed, segments, hand strung on fine wire, approximately 40 to the inch, part of the centrifugally operated, automatic short circuiting mechanism, used to convert a high torque, repulsion start, induction run, single phase motors from repulsion start to induction run operation, representative of the complex, innovative engineering, manufacturing and craftsmanship represented in this early technology, [See ID# 296, item 16.01-5], Wagner, Circa 1932

Group:

16.06 Electric Motors - Components and Parts

Make:

Wagner

Manufacturer:

Wagner Electric Mfg. Co. of Canada, Ltd., Div. of Sangamo Co. Ltd., Leaside Ont.

Model:

Serial No.:

Size:

4’ x 5/8’x 1/8’

Weight:

2 0zs.

Circa:

1932

Rating:

Exhibit, education, and research quality, illustrating the innovative engineering and craftsmanship employed in the engineering and manufacturing of repulsion induction single phase induction motors in the 1930’s

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Short circuiting ring [necklace], part of the centrifugally operated, automatic short circuiting mechanism, used to convert a high torque, repulsion start, induction run, single phase motors from the repulsion start to induction run operation.

Constructed of copper, stamp-formed, segments, Hand strung on fine wire, approximately 40 to the inch,

Construction:

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

A rare, early glimpse of the inner workings of a FHP, repulsion induction motor and the immense ingenuity, engineering and manufacturing know-how and hand craftsmanship employed in this technology - a miracle of its times. Here the challenge was to invent a reliable and economic mechanism to automatically short out the armature windings of a repulsion start motor, causing it to operate as a fixed speed induction motor, having come up to synchronous speed. The mechanism devised and used in various forms for several decades was operated through a set of armature governor weights and push rods, acting against a spring loaded barrel around which was laid a copper, segmented short circuiting ring. The device was calibrated so that the centrifugal force of the governor weights on the armature would overcome spring pressure at close to synchronous speed, allowing the barrel to move internally along the motor shaft, to a point where the copper segments, under centrifugal force, would be forced against the internal surface of the rotating commutator, thus shorting out the bars of the commutator. [see Reference #5, graphic]

Industrial Significance:

Moving electro motive equipment into the Canadian home brought with many engineering challenges, not the least of which were matters of maintenance, as well as protection against personal and propriety damage for the home owner, as na’ve equipment owner/operator. So long as motive equipment remained in an industrial setting the likelihood was that there would be experienced operating engineers who were trained to keep the equipment running smoothly. This was no longer a reasonable working assumption for motors and appliances in the home. A new technical elite was borne; they were service tradesman, largely self taught, pouring over the manuals, often with scant details, provided by manufacturers in the 1930’s through 50’s. These elites developed the skills and knowledge, as well as the test and repair facilities need to keep the electro-mechanical wonders of the time operating ‘ see test and repair equipment of the period, series 16.07.

Socio-economic Significance:

Socio-cultural Significance:

The short circuiting necklace stands as a marker of the many electro-mechanical devices, interacting and mutually supporting, on which the performance and reliability of appliances and equipment would increasingly depend, as technology moved into the Canadian home and business enterprise. It would mark the early years of a new epic, one in which Canadians would become increasingly dependent on the popular technology which flooded into their lives, and in turn on the myriad areas of technical expertise needed to keep it running smoothly.

Moving the ‘engines of industry’ in the home and places of business started with the ear-splitting noise of the internal combustion engine. By the 1920’s the principle cultural images in North America were said to be those of the engine and the mechanization that ensued. The engine had, in fact, become, in the dominant popular view, the ‘engine of progress’. It was seen everywhere, on the farm, in industry, in the shop, on the road and then, in a manner once thought not possible, in the home. A standard Canadian engineering text reported in 1946 that: ‘Ceaseless change is the keynote of the machine age and society’.Machine civilization ‘.differs from others in that it is dynamic, containing within itself the seeds of constant reconstruction’’ The authors go on to note: ‘But machine civilization based on technology, science, invention, and expanding markets must of necessity change ‘ and rapidly. The order of steam is hardly established before electricity invades it; electricity hardly gains a fair start before the internal combustion engine overtakes it.’ See reference 11 Not-with-standing a major depression and two world wars the first half of the 20th century was a period of exceptional ferment in the development and popular dissemination of FHP electric motor technology. Associated with the development were a number of driving forces, mutually supporting and interacting: Scientifically, the theoretical ground work for development of an astonishing array of electrical and electro-magnet devices had been laid by the early years of the 20th century, through the efforts of Faraday and Steinnmetz, among many others, Technologically, the work of Thomas Edison, among others, laid the foundation stones on which urban and rural electrification would proceed, enabling an new era in human experience, favoured with consumer goods and services, previously unimagined,

Economically, a favourable climate for capital investment in manufacturing capacity, methods and materials emerged, part of North America’s second industrial revolution, Socially and culturally the consumer society was born, nurtured by a pent up demand for an easier, more comfortable, pleasurable lifestyle, and the sense that 20th century electrical and electro-motive technology might be able to help. The FHP electric motor, engineered for 110 volt, single-phase house current, revolutionized life in the Canadian home. It enabled an astonishing list of appliances and labour saving devices. The revolution would take place in an astonishingly short period of time - for much of urban Canada much less than a decade. The electro-mechanical mechanization of the Canadian home was accomplished for much of urban Canada by the late 1930’s. But the early 20th century wonders of household mechanization would be dependent, in turn, on household ‘electrification’ Between them electrification and electro-mechanical mechanization changed everything. Almost over night it altered what Canadians do in the course of their day, how they live and their expectations of what their world had in store for them - in labour saving devices, devices of convenience, health and safety. The fractional horsepower electric motor [FHP] became an ubiquitous part of the Canadian household by the mid 1930’s. Cyril Veinott reported, December 1938:

‘Practically every electrified home today makes use of one or more fractional horsepower motors. This kind of motor may be used in a washing machine, refrigerator, vacuum cleaner, clock, oil burner, hair drier, room heater, sewing machine, razor, health machine, fan, air conditioner, stoker, ironed, floor waxer, or food mixer. In industrial use, the number of useful tasks performed by fractional horsepower motors is legion. In the United States alone, the value of fractional horsepower motors sold amounts to approximately $50,000,000 annually.’ See reference #1

Similarly, more than half a decade earlier Daniel Braymer had commented on the proliferation of this mind and life changing technology for home electro-mechanization. He observed that what had made it all possible was the invention of single phase alternating current motor, in a number of subtypes, small quiet, self starting, reliable and affordable motors for the home, motors which were compatible with the rapid standardization of single phase, alternating current, electrical distribution systems then spreading across north America. See reference #2 Among the types of single phase alternating current motors which quickly populated the Canadian home were: repulsion induction [see Group 16.01] for heavy duty, high starting torque applications such as refrigeration appliances; capacitor start [see Group 16.02] for advanced high torque applications, requiring quiet operation; split Phase [see Group 16.04] for light duty low starting torque applications; and shaded pole [see Group 16.04] designs for small devices such electric fans.

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

‘Fractional Horsepower Electric Motors’, Cyril Veinott, McGraw Hill New York, 1948 ‘Rewinding Small Motors’, Daniel Braymer and C.C. Roe, McGraw Hill, 1932 ‘A course in Electrical Engineering, Volume II, Alternating Current’, Chester Dawes, McGraw Hill, 1934, Starting single Phase Induction Motors, P. 362. ‘The Fractional Horsepower Motor and its Impact on Canadian Society and Culture’, G. Leslie Oliver, Material History Review, Vol. 43, Journal National Museum of Science and Technology, 1996. ‘Kelvinator Commercial Service Manual’, Kelvinator, Detroit Mich., 1928