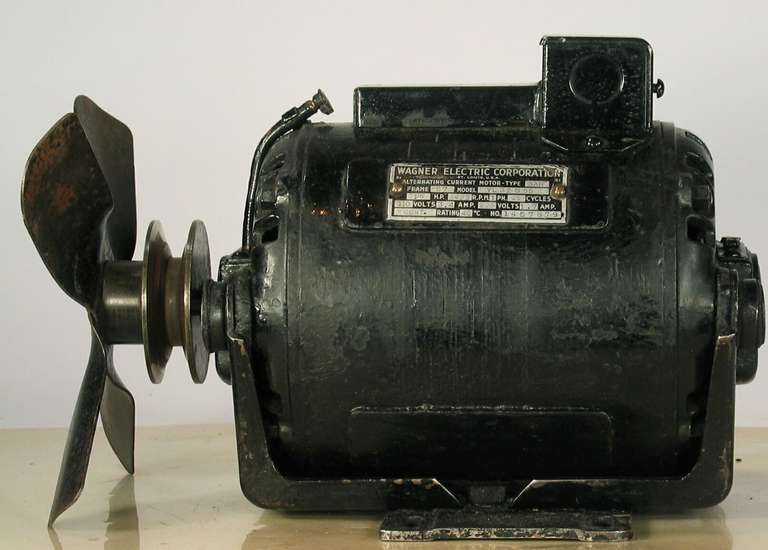

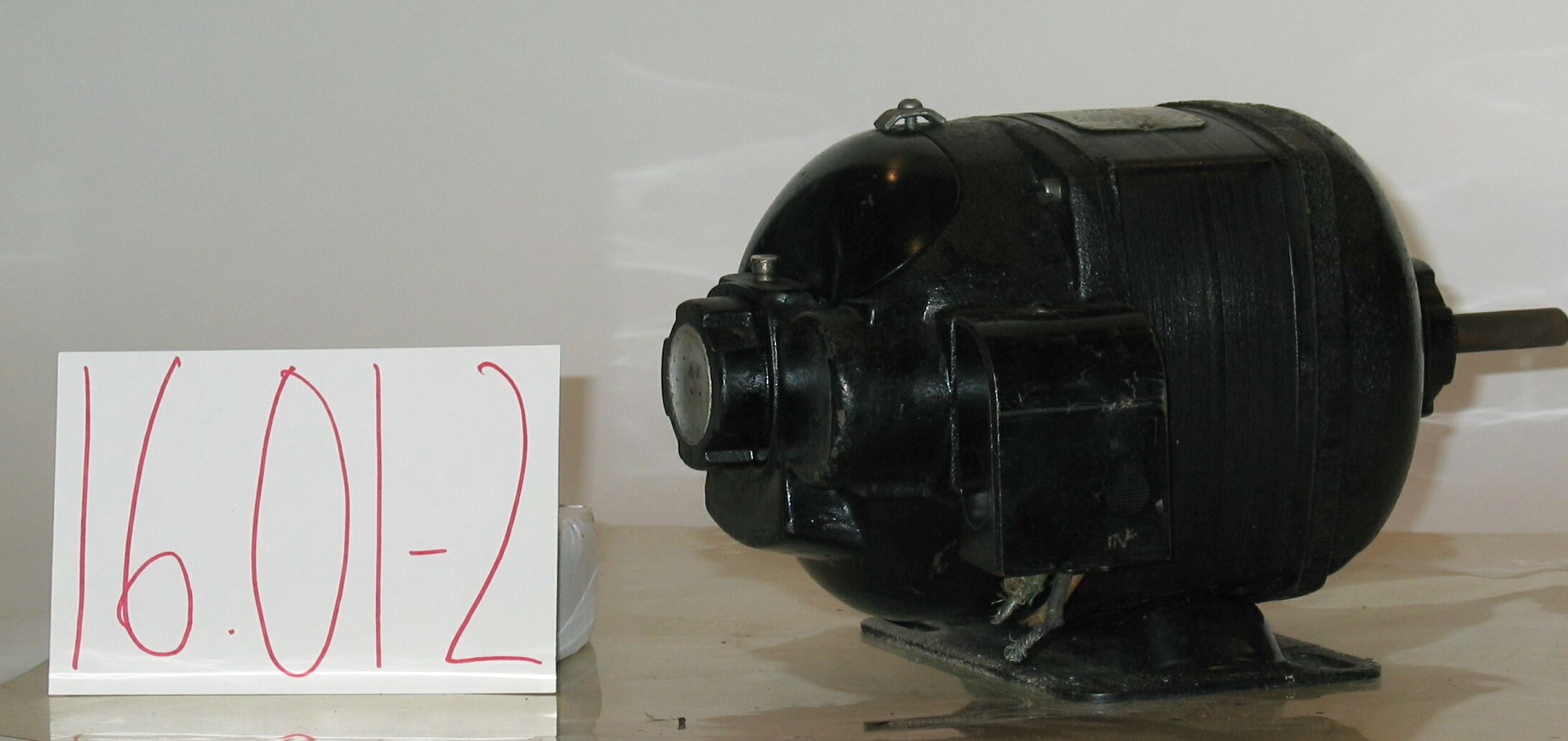

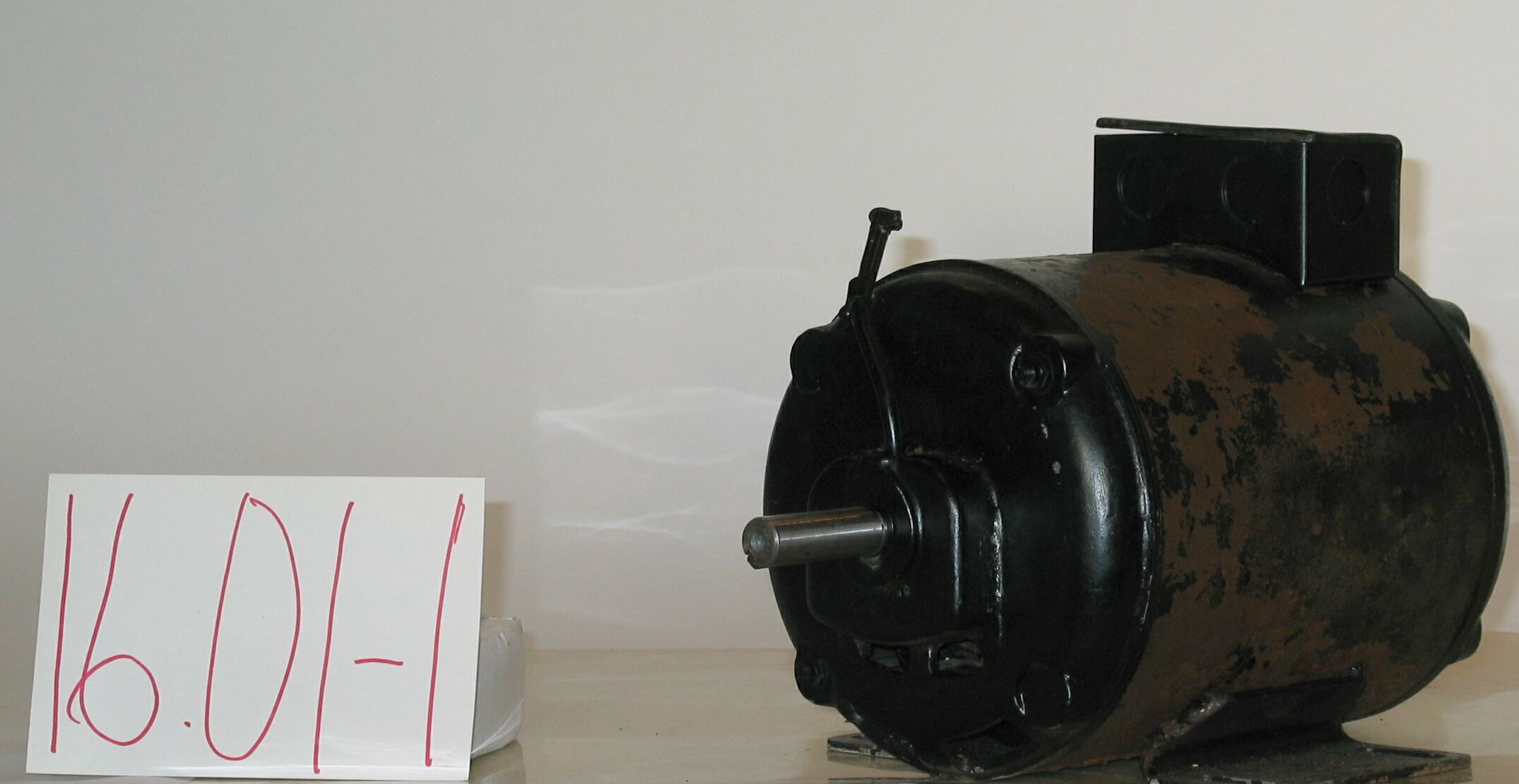

16.01-11: Wagner 1936 25 Cycle, Repulsion Induction Motor

| HHCC Accession No. 2006.179 | HHCC Classification Code: 16.01-11 |

|---|

Description:

An early 20th century, 25 cycle, repulsion induction motor with two historic innovations, a first generation, vibration isolating motor mount, and an inherent overload protector with automatic reset, helping to reduce both noise and the risk of personal and property injury in the Canadian kitchen, built in Canada for Kelvinator of Canada’s cabinet refrigerators introduced in the early 1930’s, Wagner, Circa 1936. [see also ID# 297]

Group:

16.01 Electric Motors - Single Phase, Repulsion Induction

Make:

Wagner

Manufacturer:

Wagner Electric Mfg. Co. of Canada Ltd., Div. of Sangamo Co., Ltd. Leaside Ont.

Model:

YL22B55, Type SAR

Serial No.:

1457879

Size:

12 x 8 x 8’h

Weight:

36 lbs.

Circa:

1936

Rating:

Exhibit, education, and research quality, illustrating the engineering and construction of an early, Canadian made FHP motor for a Canadian refrigerator, with vibration isolating base and inherent, automatic overload protection.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

Early 20th century, heavy duty, repulsion induction, communtating motor, 4 point, rubber, vibration isolating mount Early form of inherent overload protector with automatic reset Centrifugal brush lifting, armature short circuiting mechanism 1/6 HP Dual voltage, 110-220 volts Bronze sleeve bearings [oil well covers not included] All steel ferro-magnetic body Steel slotted base plate.

Construction:

Material:

Special Features:

Early 4 point, innovative, vibration isolating motor mounts Inherent, overload protector with automatic reset

Accessories:

Kelvinator condenser fan and compressor drive pulley assembly

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

An artifact of Canadian history telling many stories of life and times, including Canadian technological innovation, dissemination and popularization of technology for the Canadian home: An early Canadian made FHP motor for an early Canadian refrigerator manufacturer, marking the optimism of the times, the capital investment made, in spite of a period of marked economic depression

A pioneering step in quieting the Canadian kitchen. The 4 point, rubber vibration insulating base would be an historic step of significant proportion in reducing noise in the kitchen, which followed the introduction of electro-motive powered machinery into the home. It would be the first step in an evolutionary sequence which would result, in the complete disappearance of the noisy, hazards, FHP motor, embedding it within the refrigeration system itself, the hermetic refrigeration motor compressor. [see examples classification code 4.01] [see also Note 1] An early historic technology for reducing the risk of personal and property damage due to motor overload, the inherent automatic overload protector - See Note No. 1.

A combination compressor drive pulley with condenser fan, a technology widely used in the 1920’s and 30’s, here employed by Kelvinator on a Model J15 condensing unit for a home cabinet refrigerator. The pulley hub performs a dual function, acting also as the drive hub of a four blade, 9 inch propeller style condenser fan blade. Driven at 1440 RPM, the un-guarded blade would represent a significant hazard to the un-wary homeowner [see Reference No. 13, P. 66].

Repulsion induction motor technology was above all a marvel of its time, a technology born of both science and the consumer market place, a classic formula for the innovation and diffusion of popular technology, throughout the balance of the 20th century and on in to the 21st. Scientifically, the work of Faraday and many others laid much of the theoretical foundations for electromagnetic devices, the marvel of the early 20th century [much in the same way digital devices became the marvel of the early years of the 21st]. The wonders made possible by alternating current energised, rotating magnetic fields and the electric and magnetic circuitry that made them possible would soon be exploited by those interested in their application in applied electro-motive technology, including Steinnmetz and others. [See References especially #I, 2, and 5] See also ID# 296

Industrial Significance:

See also notes ID# 296

Socio-economic Significance:

Socio-cultural Significance:

Not-with-standing a major depression and two world wars the first half of the 20th century was a period of exceptional ferment in the development and popular dissemination of FHP electric motor technology. Associated with the development were a number of driving forces, mutually supporting and interacting: Scientifically, the theoretical ground work for development of an astonishing array of electrical and electro-magnet devices had been laid by the early years of the 20th century, through the efforts of Faraday and Steinnmetz, among many others, Technologically, the work of Thomas Edison, among others, laid the foundation stones on which urban and rural electrification would proceed, enabling an new era in human experience, favoured with consumer goods and services, previously unimagined,

Economically, a favourable climate for capital investment in manufacturing capacity, methods and materials emerged, part of North America’s second industrial revolution, Socially and culturally the consumer society was born, nurtured by a pent up demand for an easier, more comfortable, pleasurable lifestyle, and the sense that 20th century electrical and electro-motive technology might be able to help. The FHP electric motor, engineered for 110 volt, single-phase house current, revolutionized life in the Canadian home. It enabled an astonishing list of appliances and labour saving devices. The revolution would take place in an astonishingly short period of time - for much of urban Canada much less than a decade. The electro-mechanical mechanization of the Canadian home was accomplished for much of urban Canada by the late 1930’s. But the early 20th century wonders of household mechanization would be dependent , in turn, on household ‘electrification’ Between them electrification and electro-mechanical mechanization changed everything. Almost over night it altered what Canadians do in the course of their day, how they live and their expectations of what their world had in store for them - in labour saving devices, devices of convenience, health and safety. The fractional horsepower electric motor [FHP] became an ubiquitous part of the Canadian household by the mid 1930’s. Cyril Veinott reported, December 1938:

‘Practically every electrified home today makes use of one or more fractional horsepower motors. This kind of motor may be used in a washing machine, refrigerator, vacuum cleaner, clock, oil burner, hair drier, room heater, sewing machine, razor, health machine, fan, air conditioner, stoker, ironed, floor waxer, or food mixer. In industrial use, the number of useful tasks performed by fractional horsepower motors is legion. In the United States alone, the value of fractional horsepower motors sold amounts to approximately $50,000,000 annually.’ See reference #1

Similarly, more than half a decade earlier Daniel Braymer had commented on the proliferation of this mind and life changing technology for home electro-mechanization. He observed that what had made it all possible was the invention of single phase alternating current motor, in a number of subtypes, small quiet, self starting, reliable and affordable motors for the home, motors which were compatible with the rapid standardization of single phase, alternating current, electrical distribution systems then spreading across north America. See reference #2 Among the types of single phase alternating current motors which quickly populated the Canadian home were: repulsion induction [see Group 16.01] for heavy duty, high starting torque applications such as refrigeration appliances; capacitor start [see Group 16.02] for advanced high torque applications, requiring quiet operation; split Phase [see Group 16.04] for light duty low starting torque applications; and shaded pole [see Group 16.04] designs for small devices such electric fans. The FHP single phase induction motor, often unobtrusive, out of sight in a dark corner, has, none-the-less, been a principle foundation stone on which Canadian, popular consumer and household technology has evolved, throughout the 20th century and into the 21st - a driving force of profound, typically un-recognized, social, cultural and economic change [See reference 6]. Electro-motive technology [the FHP motor], along with electric and electronic communications technology [the telephone and broadcast radio] would invade the Canadian home starting in the 1920’s. Throughout the balance of the 20th century these technologies would trigger a vast, new, popular consumer culture, a ‘popular technological revolution’. Yet, simply because technology has so shaped the Canadian reality, it has also shaped much profound Canadian though about the technological experience, its meaning and significance for humanity. Included among the works of Canadian writers with an international reputation are: Arthur Kroker, George Grant, Ursala Franklin, Heather Menzies, among many others [See references 7, 8, 9, and 10]. From the vantagepoint of the 21st century noted Canadian writer Jane Jacobs asks, ‘Now we stand at another monumental crossroad, as agrarianism gives way to a technology-based future. How do we make this shift without losing the culture we hold dear’ [See reference 11]

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

‘Fractional Horsepower Electric Motors’, Cyril Veinott, McGraw Hill New York, 1948 ‘Rewinding Small Motors’, Daniel Braymer and C.C. Roe, McGraw Hill, 1932 ‘Theory and Application of Capacitor-Start Induction Motors’, G. L. Oliver, Bachelor Thesis ,University of Toronto, Session 1951-52 ‘Modern Refrigeration and Air Conditioning’, Electric Motors, Chapter 7, Andrew Althouse and Carl Turnquist, Goodheart-Wilcox, 1960 ‘A course in Electrical Engineering, Volume II, Alternating Current’, Chester Dawes, McGraw Hill, 1934, Starting single Phase Induction Motors, P. 362. ‘The Fractional Horsepower Motor and its Impact on Canadian Society and Culture’, G. Leslie Oliver, Material History Review, Vol. 43, Journal National Museum of Science and Technology, 1996. ‘Technology and the Canadian Mind, Innis/ McLuhan/Grant’, Arthur Kroker, New World Perspectives, 1984. ‘Technology and Empire’, George Grant, Anansi, 1969, ‘The Real World of Technology’, Ursula Franklin, Anansi, 1993. ‘Fast Forward and Out of Control’, Heather Menzies, Macmillan, 1989 ‘Dark Ages Ahead’, Jane Jacobs, Random House, 2004 ‘Kelvinator Service Manual’, Kelvinator of Canada, January, 1935, P.56 ‘Kelvinator Commercial Service manual’, Kelvinator, Detroit Mich., 1928

Notes:

The early form of inherent overload protector, with automatic reset shown here represented a world change from the earlier technology commonly employed the ‘fusetron’. The fusetron was a slow blow fuse engineered to take the high starting current associated with inductive loads, but to open circuit in response to prolonged over load conditions. Lacking a recycling capability, it left the homeowner vulnerable. As a consequence many homeowners would find their refrigerator off, with resultant food spoilage. The inherent motor overload protector with an automatic recycling capability would be the next step in the innovation process.

Related Reports:

- CMX02 exhibit March 2002, Item R3