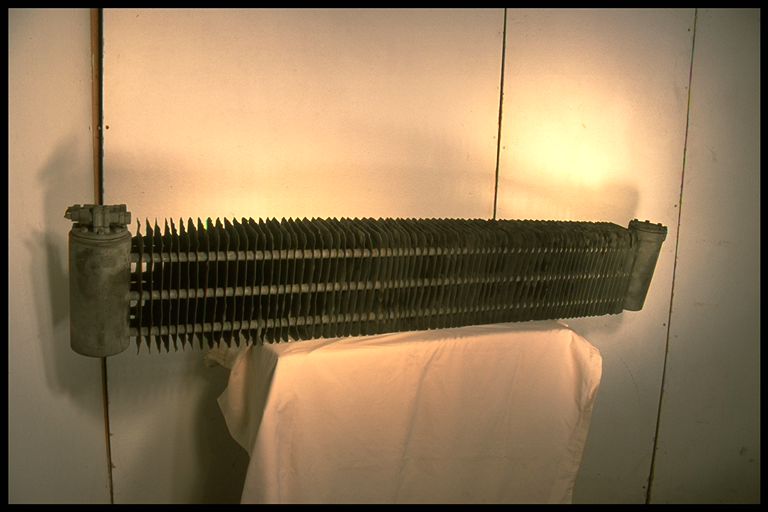

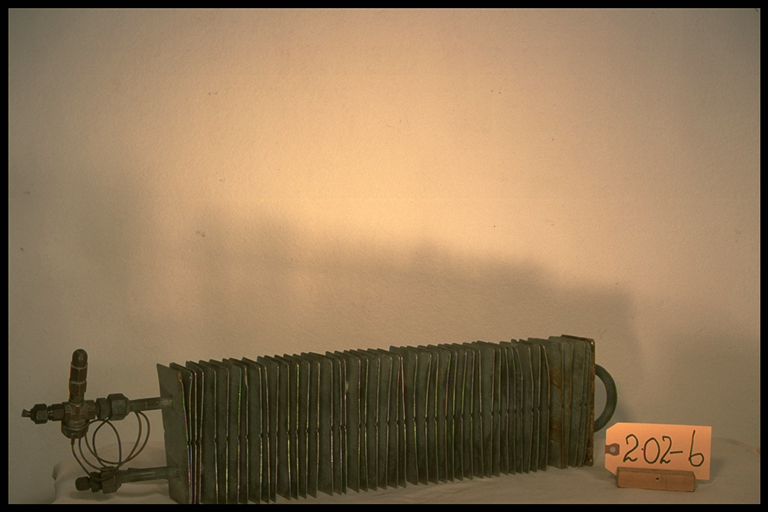

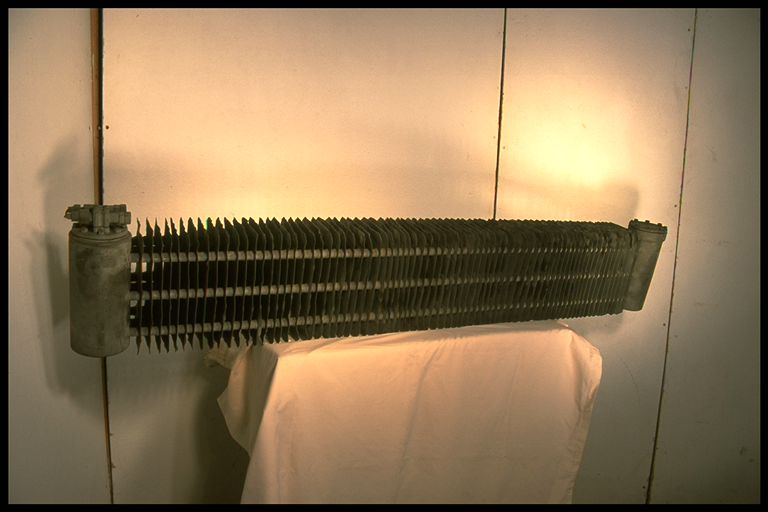

2.02-5: Frigidaire 1926 Six Tray, Ice Maker Evaporator

| HHCC Accession No. 2003.025 | HHCC Classification Code: 2.02-5 |

|---|

Description:

Six tray, ice maker evaporator with low-side float, using an early form of modular construction, in tinned copper tube and brake formed copper sheet. Cooling unit with shiny tinned copper ice cube trays with gleaming polished chrome tray pulls, for large, commercial, ice maker, cabinet refrigerator, similar to the smaller items #022, #023, #024, Of the genre of the first commercial, North American ice making machine, Frigidaire, 1926

Group:

2.02 Refrigerating and Air Conditioning Evaporators - Commercial

Make:

Frigidaire

Manufacturer:

Frigidaire Division, General Motors Corp.,Dayton Ohio

Model:

Serial No.:

A13350

Size:

11x 14x 23’h

Weight:

60 lbs

Circa:

1926, (Frigidaire Manual SER-405, shows product as discontinued in 1928)

Rating:

Exhibit, demonstration, education and research quality

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, commercial and consumer technology.

Type and Design:

Flooded evaporator with low-side float in tinned copper tube and brake formed copper sheet, similar to #022, #023 and #024

Construction:

Similar to #024, this icemaker is constructed in tinned, heavy copper plate, with 5’ dia., 14 inch, brass float chamber, with brass, flange mounted float assembly, calibrated for S02 refrigerant. It uses a flattened, oval, 5 pass, 1/2’ copper distributing tubes, rather than round ones, presumably in an attempt to improve the heat transfer coefficient, without side box fin. Recessed suction line shut off valves with gas tight caps.

The construction of the ice cube trays demonstrates much more sophistication in manufacturing methods than in item #024. for example. The stamped, deep draw, formed tray with rolled edges, in high gloss tinned finish was a ploy to capture the interest of prestige merchants and restaurateurs of the day.

Material:

The heavy construction throughout marks the respect that the manufacturer held for SO2 refrigerant, its noxious and corrosive properties.

Special Features:

The early form of modular construction employed allowed the manufacturer to ‘grow’ their evaporators using standard off the shelf components, with relatively predictable performance.

The ice cube trays are believed to have been re-tinned and the fronts re-chromed, as part of the refurbishing of the icemaker in T. H. Oliver’s repair shop in Aurora Ontario prior to re application in the 1950’s.

Accessories:

Heavy 4 point hanger system in double dip galvanised strap iron

The inclusion of the 8 inch x 3/8 garage bolts with heavy galvanised steel spacer sleeves for hanging the cooling unit from the top of the refrigerator cabinet illustrates the type of cabinet construction of the day, 2’ natural cork

Capacities:

This 6 tray ‘ice making machine’ like the smaller ones in the series [See #024], employs a clever double tray module that converts to frozen food storage, or to ice making with the inclusion of a sliding shelf

Frigidaire’s manual SER-45, Chapter 1A, P. 25, suggests such evaporators were rated at about 20 lbs of ice per freezing and required about 8 lbs of SO2 refrigerant to flood the evaporator, sufficient to clear the household and the neighbourhood, if a serious leak ever occurred

Performance Characteristics:

Operation:

Control and Regulation:

Liquid refrigerant float operated metering device

Targeted Market Segment:

Large commercial food stores, large private estates, restaurants and institutional use

Consumer Acceptance:

Merchandising:

The stamped, deep draw, formed tray with rolled edges, in high gloss tinned finish with chrome fronts was a ploy to capture the interest of prestige merchants and restaurateurs of the day.

Market Price:

Technological Significance:

See background notes on technological significance of early mechanical cooling units (evaporator), THOC-HVACR inventory item 011.

This specimen is representative of the proliferation of models and sizes of low-side float operated evaporators of the period, largely by Kelvinator and Figidaire, as they attempted to stretch this ice making technology to its limit. Dinosaur like, costly, complicated and trouble prone by comparison with the evaporator technologies that would shortly follow, this genre would largely disappear from manufacture’s catalogues by the early 1930’s, although would be operational in the field until after WWII ‘ requiring repair shops to rebuild an calibrate floats and needle seats.

To contrast the weight, size, seeming complexity, as well as materials and manufacturing costs with the technology reflected in inventory items 015 to 021 is instructive. The classic process of progressive simplification in technological innovation and change is well exemplified.

None-the-less this large, modular designed icemaker, ‘grown’ using the same flooded evaporator technology as shown in #024. for example, feed the seemingly endless and ever growing North American market for iced beverages, deserts and product cooling of all sorts . This value set, a distinguishing mark of the North American culture of the times was not to be found to the same extent in urban European setting of the same period.

The stage had been set and the market established for the design and development of the automatic ice cube-making machine, to appear on the market in Canada by the early 1950’s. Icemakers of the general design shown here would prevail up to that time and beyond. .

Industrial Significance:

With complex, demanding construction, the evaporator would make many demands on manufacturing and materials engineering in the early years of the 20th century.

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

Frigidaire Installation and service manual SER-45