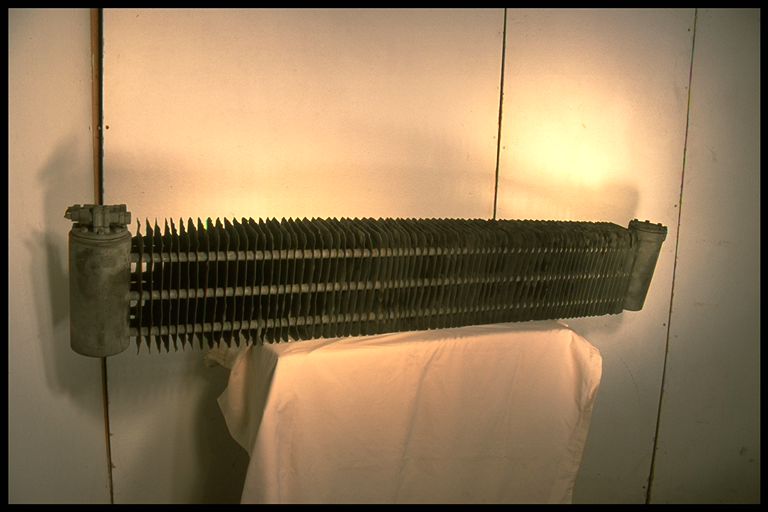

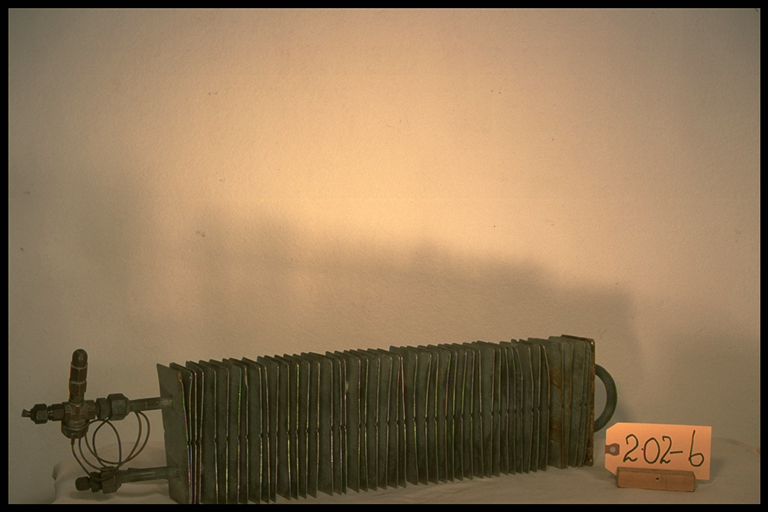

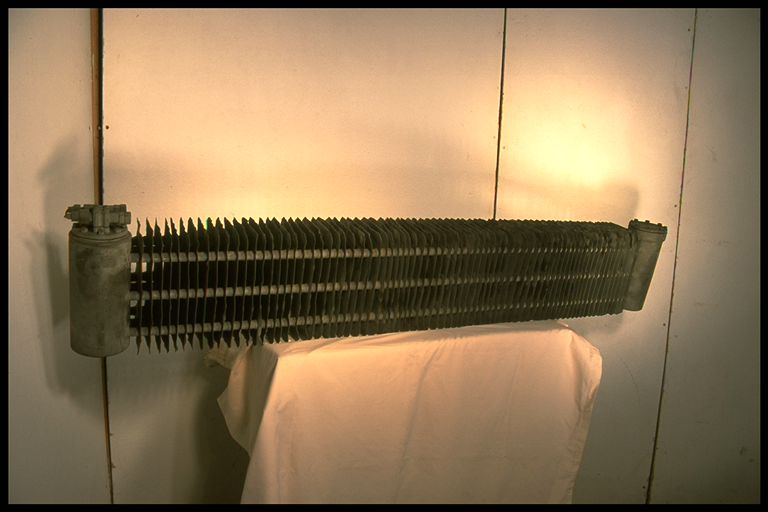

2.02-8: Woods (?) 1950 Farm Milk Can Cooler

| HHCC Accession No. 2003.029 | HHCC Classification Code: 2.02-8 |

|---|

Description:

A mid 20th century, drop-in, evaporator for farm milk can cooler, with electric motor driven water agitator, built in stove pipe configuration, circa 1950

Group:

2.02 Refrigerating and Air Conditioning Evaporators - Commercial

Make:

Believed to be Woods, Quelph Ontario Delco motor, St Catharines Ont.

Manufacturer:

Possibly Woods Co, Quelph Ontario, manufacturer and supplier of farm equipment McKinnon Industries, St Catharines Ont.

Model:

Delco motor, Model M2572A2,

Serial No.:

Delco motor serial 6-7-50

Size:

8x 9x 33’h

Weight:

50 lbs

Circa:

1950

Rating:

Exhibit, education and research quality exemplifying farm milk can cooling at mid century [20th] prior to disappearance of the farm milk can and the introduction of farm bulk milk cooling.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

The evaporator, highly innovative for the period, was, in some ways, a state-of-the-art answer to challenge of manufacturing and marketing an inexpensive ‘drop-in’ cooler. It was designed for use in the new and replacement marketplace of the period. In the later it was intended to up-grade the traditional can milk cooler, typically consisting of a concrete tank full of water, cooled by block ice or by copper refrigerant piping run around the interior wall.

Construction:

Assembled in a 6’ heavy gauge stove pipe casing, the evaporator consists of 17 coils of ‘ in, copper wound around the shaft of a sump-pump style water agitator. Fitted with a large suction line accumulator the evaporator was feed through a simple capillary line flow control.

Resting on top of the assembly, mounted on a 2 in. circular wooden in pine plug, is a ‘ HP split phase motor directly coupled to the pump shaft below, yielding a simple but often troublesome milk can cooler. The agitator pump bearings, water lubricated, were short lived, often resulting in a characteristic rattle that could be heard a quarter of a mile from the barn. The pump was prone to plugging up with foreign material reducing the cooling capacity and causing refrigeration system malfunction.

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Typically coupled to an air-cooled condensing unit in the milk house, the system would operate on an automatic thermostat, set to keep the water bath temperature just below 40 degrees F. See for example artifact 4.02-20, manufactured by Silver King Toronto.

Control and Regulation:

Targeted Market Segment:

New and replacement farm, can milk cooler market. Adored by farm equipment dealers it could be dropped into an existing milk cooler tank with a minimum of installation time and skills.

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

A special marker in time, the device represented a relatively low cost solution to simplify the farm milk can cooling process. Such innovations would be relatively short lived, however, with the introduction of farm bulk milk coolers in many areas in the early 1960’s

Industrial Significance:

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection