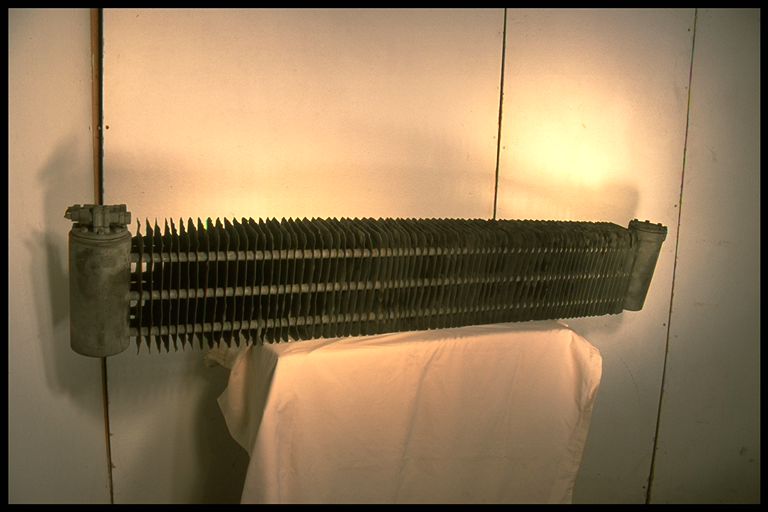

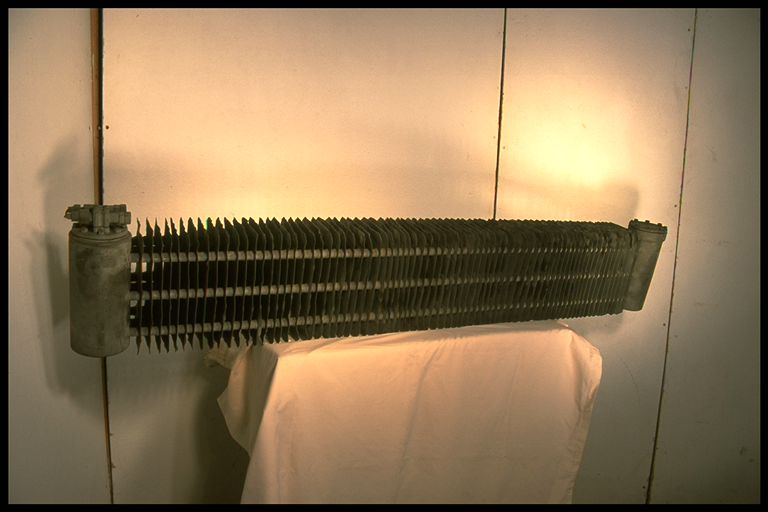

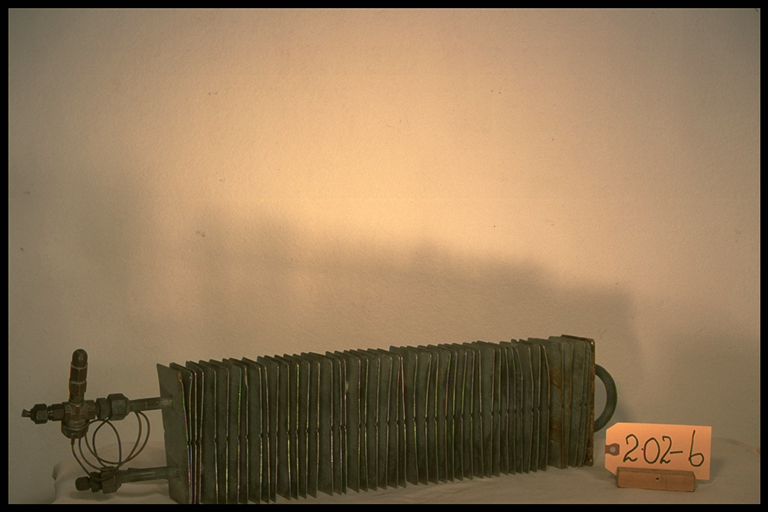

2.02-6: 1945 Early Copper Tube and Aluminium Fin, Static Evaporator

| HHCC Accession No. 2003.026 | HHCC Classification Code: 2.02-6 |

|---|

Description:

Early copper tube and aluminium fin, static evaporator for small commercial refrigerated fixture, representative of a new, mid-century, high conductivity, high heat transfer cooling unit equipped for thermostatic expansion valve, Circa 1945

Group:

2.02 Refrigerating and Air Conditioning Evaporators - Commercial

Make:

Unknown

Manufacturer:

Unknown

Model:

Serial No.:

Size:

29x 6x 3’

Weight:

3 lbs

Circa:

1945

Rating:

Exhibit, education and research quality, exemplifying mid-century evaporator design trends

Patent Date/Number:

Mason Mfg. Co TX valve Pat. #1964687 (1935)

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

Type and Design:

A static fin evaporator, used for gravity induced cooling following the design idiom of the period. Fin spacing was wide to allow for frost build up and to facilitate slow moving, gravity induced airflow. Forced air evaporators were not commonly found in small refrigeration applications until the 1950’s and after. The small high efficiency forced air evaporator with automatic defrost was still several decades away. A significant barrier was the availability of small reliable fan motors for low temperature applications [See Classification 1600, Electric Motors].

The refrigeration evaporator was still perceived somewhat as melting block of ice, providing cooling, while maintaining high humidity conditions within the refrigerated space. Little engineering data were available for the design of forced air systems and their performance, especially with respect to drying effect on product.

Secondary, finned, surfaces were still relatively rare, as can be seen in artifacts 011 to 025.

Construction:

Material:

‘ ‘ copper tube with forced fit aluminium 3x 6’ fins @ 1/2’ centres

Special Features:

Accessories:

Mason Mfg. Co. expansion thermostatic valve, with adjustable superheat

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

The 1950’s brought with them a flood of demands for new small refrigeration fixture applications, for example, for reach-in refrigerators to display cases of all types. The application of secondary, finned surface and the development of a small thermal expansion valve with adjustable superheat provided the market with the first big steps, through vastly improved thermal heat transfer efficiency, as well as the efficient use of refrigerant passages by improved refrigerant flow control.

Industrial Significance:

Socio-economic Significance:

Socio-cultural Significance:

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection