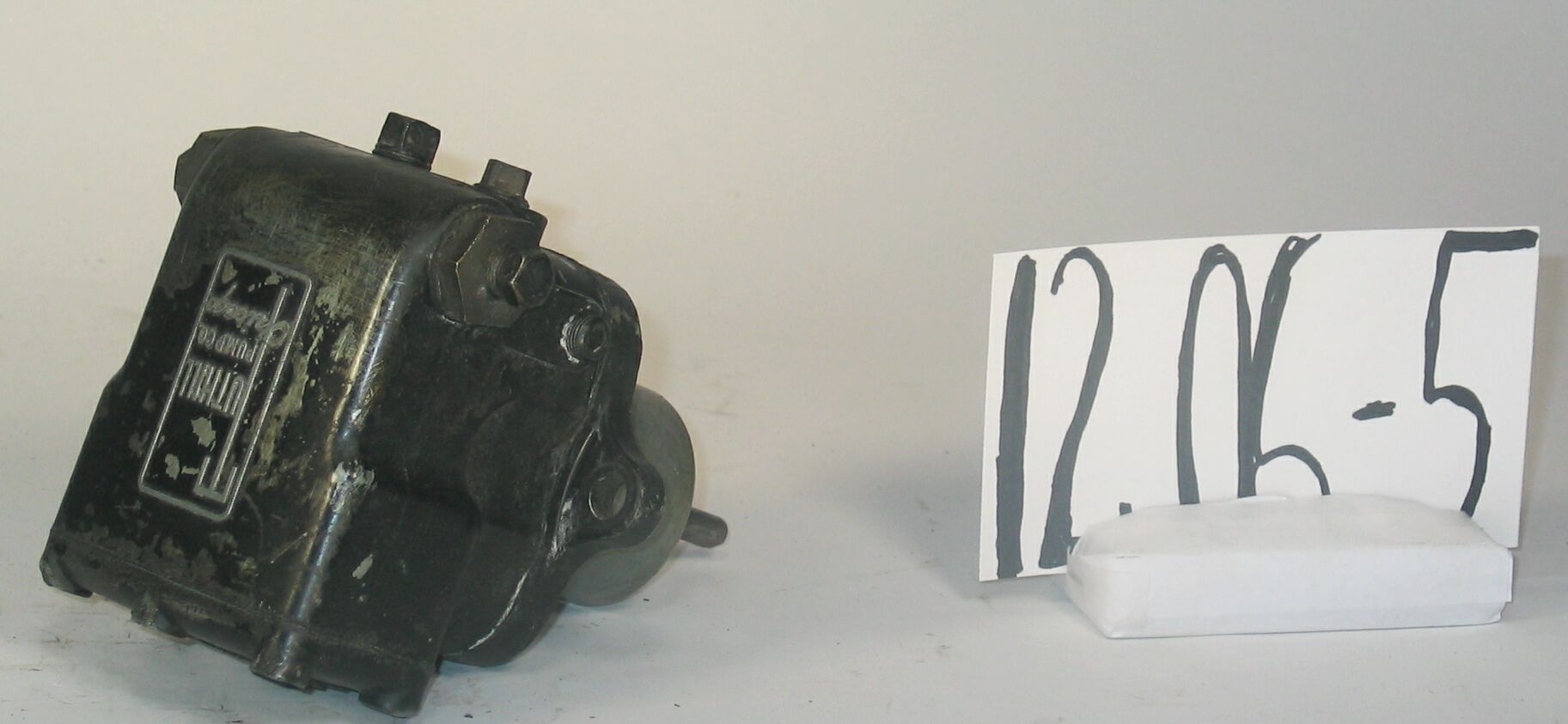

12.06-12: Detroit Lubricator 1958 Two Stage Rotary, Gear Style Pump

| HHCC Accession No. 2006.153 | HHCC Classification Code: 12.06-12 |

|---|

Description:

Commercial, high capacity, two stage rotary, gear style pump, in cast steel body, with barrel and flange motor mount and brass drive coupling. A product of post W.W.II compacted and functionally integrated engineering. [4th wave], it stands as a marker of the wide spread application of high pressure atomizing oil burner technology to commercial and institutional uses in Canada in the last half of the 20th century, Detroit Lubricator, Circa 1958

Group:

12.06 Pressure Atomizing Oil Burner Equipment and Systems - Fuel Pump Assemblies

Make:

Detroit Lubricator

Manufacturer:

Detroit Lubricator, Detroit

Model:

CR8-333

Serial No.:

X11322J

Size:

7 x 9 x 7’ h , plus piping

Weight:

15 lbs.

Circa:

1958

Rating:

Exhibition, education, and research quality, illustrating the engineering and design of latter 20th century compact fully integrated oil pump assemblies designed for commercial and institutional applications.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

This assembly was used in York County [York Region] north of Toronto in the 1930’s

Type and Design:

Two stage rotary gear style pump, Heavy cast steel body Two hole flange and barrel mount Close, direct motor drive, with brass drive coupling Internal pressure regulating valve, cu-off valve and oil bypass Inlet oil strainer, Part of a 4th wave in engineering design, characterized by compacted and functionally integrated engineering.

Construction:

Material:

Special Features:

Original line fittings and tubing illustrating the historic trade practices of the period

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

From the vantage point of the early 21st century, the evolution of oil fired, automatic home heating equipment would be seen as generally advancing in four broad waves, each of which would take place over a considerable period of time, each producing many variations of the genre: Vaporizing, non-motorized and non-electrified, technology [see Group 11.01 artifacts, no. 11.01-1] Elemental, motorized, platform mounted technology with peripheral piping and valving components [see Group 12.01, artifact no 12.01-1, and pump assembly 12.06-1] Compacted motorized technology with inherent, peripheral component parts engineered into the pump assembly [see pump assembly Group 12.06, artifact, and 12.06-2] Functionally integrated, motorized technology, beyond being compacted, a number of functions would be smoothly integrated into a single pump assembly, including piping and valving [see Group 12.01, artifact 12.01-2 and pump assembly 12.06-2] This pump assembly stands as an example of a high capacity, advanced 4th wave fuel oil pump technology, compact and functionally integrated in heavy cast steel body, designed for commercial and institutional applications.

Industrial Significance:

Detroit Lubricator would be one of a relatively few engineering manufactures that would produce for both the oil heating and refrigeration sectors of the HVACR industry. Their reputation in regulating valves and electric controls for refrigeration systems was well established ‘ see group classification 7.02 and 3.02.

Socio-economic Significance:

Socio-cultural Significance:

In spite of an inherently cautious Canadian public and its attitude towards new fangled, electro-mechanical contraptions in the early years of the 20th century, consumer interest in automatic oil heating equipment for the home grew surprisingly rapidly - amongst those that could afford to aspire to such luxuries in a period of national economic depression. The massive conversion market [conversion of coal and wood fired central heating systems to automatic oil heating] of the 1940’s and 50’s, in much of Canada was a growth market for the industry , in commercial and institutional applications as well as residential

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

For an account of the construction, operation, installation and servicing of fuel oil pump assemblies see ‘Better Oilheating, A service Guide, Operation and Maintenance of Oil Burners, Second Edition, 1959, Fueloil and Heat, N.Y.