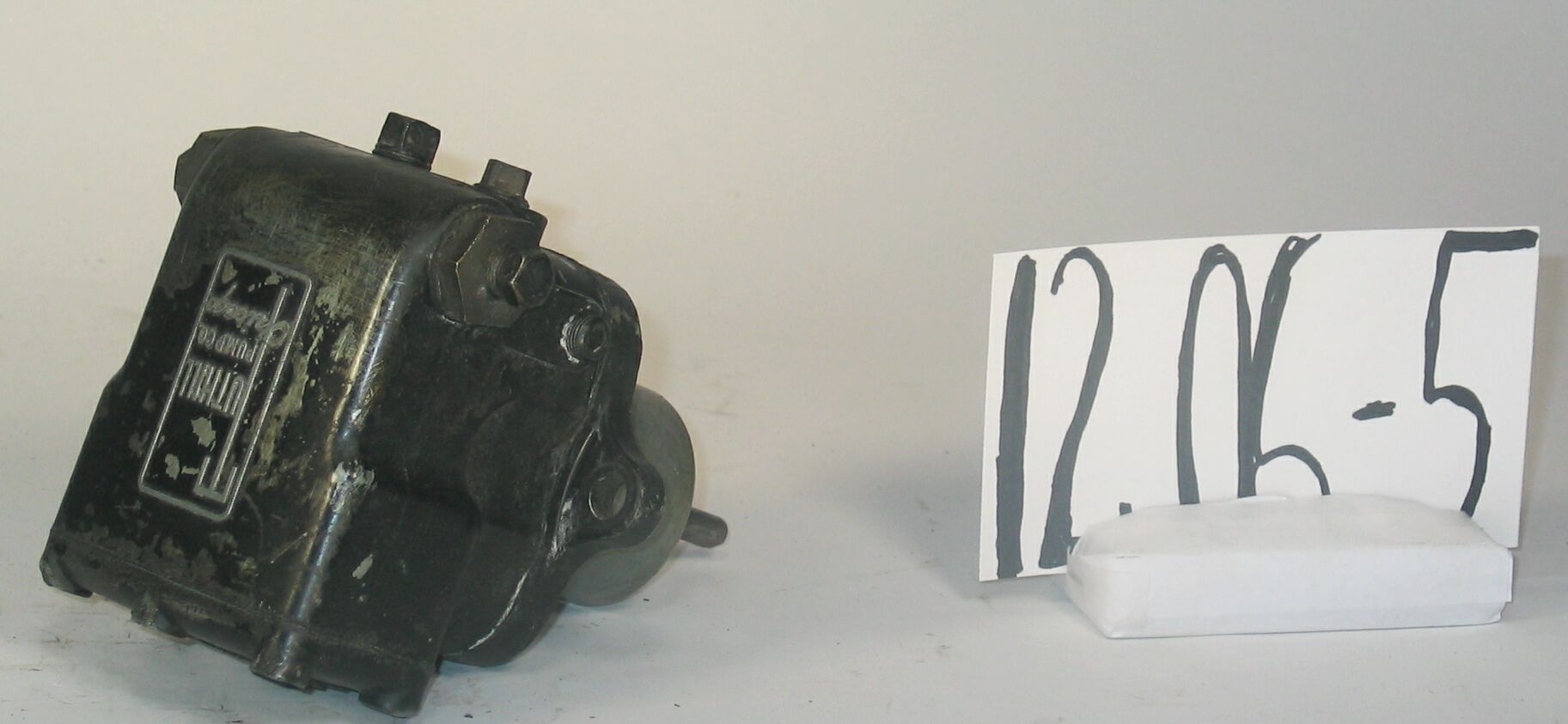

12.06-2: 1929 Rotary Fuel Oil Pump for Automatic Home Heating

| HHCC Accession No. 2006.145 | HHCC Classification Code: 12.06-2 |

|---|

Description:

A rotary, low pressure, fuel oil pump for automatic home heating, with carbon rotor separator blades, heavy steel rotor, in cast and machined steel body equipped for 4 bolt flange motor mounting, built-in, brass, automatic pressure regulating valve with manual adjustment, beginning to suggest the early years of the 4th wave in engineering design, characterized by compacted, integrated fuel oil pump assemblies, manufacturer unknown, Circa 1929

Group:

12.06 Pressure Atomizing Oil Burner Equipment and Systems - Fuel Pump Assemblies

Make:

Unknown See Note 1

Manufacturer:

Unknown See Note 1

Model:

Unknown

Serial No.:

Size:

6 inch dia x 4 inch long

Weight:

14 lbs.

Circa:

1929

Rating:

Exhibition, education, and research quality, illustrating the engineering and design of carbon blade rotary fuel oil pumps for automatic home heating in Canada in the late 1920’s, a period in which the trend to increasingly compacted and functionally integrated configurations was evident [Wave 4].

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

This assembly was used in York County [York Region] north of Toronto in the 1930’s

Type and Design:

With steel body equipped for 4 bolt flange mounting [facilitating compact,coaxial motor drive], built-in, brass, automatic pressure regulating valve with manual adjustment, the technology represented here begins to suggest the 4th wave in engineering design, moving to motorized burner technology, with increasingly compacted and functionally integrated fuel oil pump assemblies with piping and pressure valving buried within the body of the pump assembly. A motorized, rotary, low pressure, fuel oil pump Four natural carbon separator, rotor blades, heavy steel rotor, heavy cast and machined steel body equipped for 4 bolt flange mounting, built-in, brass, automatic pressure regulating valve with manual adjustment,

Construction:

Material:

Special Features:

Natural carbon separator blades

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

From the vantage point of the early 21st century, the evolution of oil fired, automatic home heating equipment would be seen as generally advancing in four broad waves, each of which would take place over a considerable period of time, each producing many variations of the genre: Vaporizing, non-motorized and non-electrified, technology [see Group 11.01 artifacts, no. 11.01-1] Elemental, motorized, platform mounted technology with peripheral piping and valving components [see Group 12.01, artifact no 12.01-1, and pump assembly 12.06-1] Compacted motorized technology with inherent, peripheral component parts engineered into the pump assembly [see pump assembly Group 12.06, artifact, and 12.06-2] Functionally integrated, motorized technology, beyond being compacted, a number of functions would be smoothly integrated into a single pump assembly, including piping and valving [see Group 12.01, artifact 12.01-2 and pump assembly 12.06-2] By the early 1930’s the Canadian oil heating industry was progressing well beyond simple, gravity feed, vaporizing oil-heating equipment [wave 1] and elemental, motorized, electrified, designs [wave 2], to increasingly more compacted and functionally integrated engineering designs. Seen here in the compact, coaxial motor drive flange and the built in pressure valve and piping passages. This pump assembly is, then, an early marker of the 4th design wave A hallmarks of the design is the use of carbon, separator, rotor blades. Carbon was a natural choice, as a natural substance, which tended to be self lubricating and self-positioning, wearing to cylinder wall to maintain a close running tolerance and quiet operation ‘ all this in a period long before the availability of more sophisticated engineering materials A hallmark of this technology of the period would also be its massive weight, as represented here by this 10 lb., toe crushing, partial pump body. But the look was a preferred one in the culture of the times, by a public still spooked by the seeming inherent dangers represented by un-attended, automatic oil heating equipment in the home. Among other things it must look, feel and in fact be solid.

Industrial Significance:

A marker of the sophisticated machining and manufacturing techniques of the times, using the relatively crude machine tools available.

Socio-economic Significance:

Socio-cultural Significance:

In spite of an inherently cautious Canadian public and its attitude towards new fangled, electro-mechanical contraptions in the early years of the 20th century, consumer interest in automatic oil heating equipment for the home grew surprisingly rapidly - amongst those that could afford to aspire to such luxuries in a period of national economic depression. Household machines, refrigerators and oil burners in the basement, would be the “show and tell” subjects of the day for many upper-middle class homeowner, those with interests in ‘conspicuous wealth’, anxious and willing to demonstrate their latest life style purchases. The master narrative told here, the one to which almost all others relate, is that of the emergence of ‘machinery in the Canadian home’. As the 20th century dawned, Canadians, accustomed to their resource-based, extractive economy were used to transportation, traction and motive power machines in farm, mill and factory, where they seemed to rightfully belong. With the 1920’s, however, all that was about to change ‘ and change dramatically Here-to-for, the familiar motive power, rotating machines of farm, mill and factory were driven by central station power plants, water, steam and later internal combustion engines. But it was with the advent of motive power packaged in unitary, moveable forms, as in the ‘stationary’, gasoline engine [explosion engine] and the electric motor that a new era in motive power was made possible for home, as well as for farm, mill and factory applications It was principally the fractional horsepower, single phase, induction electric motor [see note #1] that made possible the introduction of machinery into the home, and with it ‘the end of quiet’ [see historical artifacts Classification Group 16,00, see Reference #1].

With the introduction of self powered machines into the home also came the introduction of automated, self regulating machinery, machinery that would turn iteself on and off, without the touch of human hand - the refrigerator, oil burner and water pump. These automated, inanimate objects also introduced new rhythms into the home, each with its distinctive hum and beat, each coming on and off with its own unique operating rhythm. The aroma of oils, vapours and materials, once foreign in the household, would also fallow. The 20th century ‘electro- mechanical’ Canadian home had arrived, much the same as the digital Canadian home would arrive in little more than half a century later ‘ changing all. The consequences were profound, spelled out in terms of the social, cultural and economic changes wrought.

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

- Instructions for Installation, Fess Automatic Oil Burners, TypyJR, TypeF, DA, DS, DAE, D3, BI, Fess Oil Burners of Canada Limited, Toronto, undated

- Fractional Horsepower Electric Motors, Cyril Veinott, McGraw-Hill, New York, 1948

Notes:

Possibly Fess Oil Burners of Canada, suggested by the black/green enamel characteristic of the manufacturer For an account of the construction, operation, installation and servicing of fuel oil pump assemblies see ‘Better Oilheating, A service Guide, Operation and Maintenance of Oil Burners, Second Edition, 1959, Fueloil and Heat, N.Y.