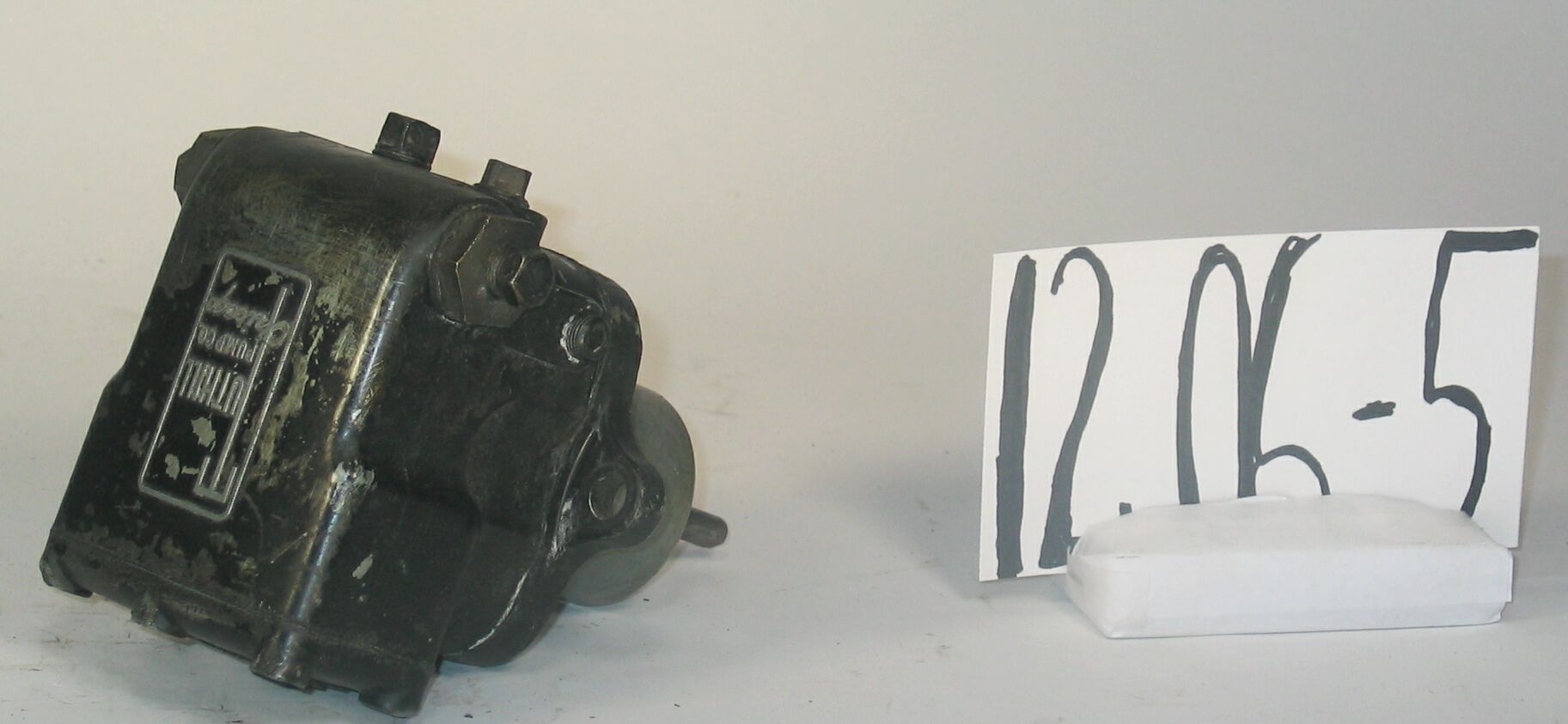

12.06-7: Webster 1955 Single Stage Rotary Gear Pump

| HHCC Accession No. 2006.150 | HHCC Classification Code: 12.06-7 |

|---|

Description:

Two stage rotary, gear style pump, in cast steel body with extended shaft, and Webster stylish logo, carrying a Canadian manufacturer’s name; an example of beautifully compacted and functionally integrated engineering. [4th wave] and of the rapidly approaching mature market years for high pressure, 100 psi. oil burner technology, bringing with it a giant bulge in the percentages of Canadian home owners and businesses that would enjoy automatic heating, Webster/ Canadian Acme Screw and Gear, Circa 1955

Group:

12.06 Pressure Atomizing Oil Burner Equipment and Systems - Fuel Pump Assemblies

Make:

Webster

Manufacturer:

Canadian Acme Screw and Gear, Toronto

Model:

2R-111D-AH

Serial No.:

Body stampings 19841

Size:

5 x 7 x 5’ h

Weight:

10 lbs.

Circa:

1955

Rating:

Exhibition, education, and research quality, illustrating the engineering and design of latter 20th century compact fully integrated oil pump assemblies for the Canadian homes and businesses.

Patent Date/Number:

Provenance:

From York County (York Region) Ontario, once a rich agricultural hinterlands, attracting early settlement in the last years of the 18th century. Located on the north slopes of the Oak Ridges Moraine, within 20 miles of Toronto, the County would also attract early ex-urban development, to be come a wealthy market place for the emerging household and consumer technologies of the early and mid 20th century.

This artifact was discovered in the 1950’s in the used stock of T. H. Oliver, Refrigeration and Electric Sales and Service, Aurora, Ontario, an early worker in the field of agricultural, industrial and consumer technology.

This assembly was used in York County [York Region] north of Toronto in the 1930’s

Type and Design:

Two stage rotary gear style pump, Heavy cast steel body Two hole flange and barrel mount Close, direct motor drive, with extended shaft Internal pressure regulating valve, cu-off valve and oil bypass Inlet oil strainer, Part of a 4th wave in engineering design, characterized by compacted and functionally integrated engineering. A marker of the rapidly approaching mature market years in Canada for high pressure, 100 psi., gun type oil burner technology.

Construction:

Material:

Special Features:

Accessories:

Capacities:

Performance Characteristics:

Operation:

Control and Regulation:

Targeted Market Segment:

Consumer Acceptance:

Merchandising:

Market Price:

Technological Significance:

From the vantage point of the early 21st century, the evolution of oil fired, automatic home heating equipment would be seen as generally advancing in four broad waves, each of which would take place over a considerable period of time, each producing many variations of the genre: Vaporizing, non-motorized and non-electrified, technology [see Group 11.01 artifacts, no. 11.01-1] Elemental, motorized, platform mounted technology with peripheral piping and valving components [see Group 12.01, artifact no 12.01-1, and pump assembly 12.06-1] Compacted motorized technology with inherent, peripheral component parts engineered into the pump assembly [see pump assembly Group 12.06, artifact, and 12.06-2] Functionally integrated, motorized technology, beyond being compacted, a number of functions would be smoothly integrated into a single pump assembly, including piping and valving [see Group 12.01, artifact 12.01-2 and pump assembly 12.06-2] This pump assembly stands as an example of advanced 4th wave fuel oil pump technology, compact and functionally integrated in heavy cast steel body. A marker of the now rapidly approaching mature market years for high pressure, 100 psi. oil burner technology, leaving room for a new generation of ultra-high pressure, 200 psi. technology.

Industrial Significance:

Webster a respected US manufacturer of oil burner components, including ignition transformers [see ID#12.07-1 and 2] and oil pumps, would like Tuthill seek Canadian partners in the post WWII period to take advantage of the rapid growth of the oil heating market in Canada.

Socio-economic Significance:

The latter part of the 20th century would bring with it a giant bulge in the percentages of Canadian homeowners and businesses that would enjoy automatic heating - likely for the first time.

Socio-cultural Significance:

In spite of an inherently cautious Canadian public and its attitude towards new fangled, electro-mechanical contraptions in the early years of the 20th century, consumer interest in automatic oil heating equipment for the home grew surprisingly rapidly - amongst those that could afford to aspire to such luxuries in a period of national economic depression. Household machines, refrigerators and oil burners in the basement, would continue to be the “show and tell” subjects of the day for many home owners through the 1940’s and 50’s, as these technologies became more highly developed, reliable and increasingly affordable for working Canadians. The massive conversion market [conversion of coal and wood fired central heating systems to automatic oil heating] of the 1940’s and 50’s, in much of Canada was a growth market for the industry

The master narrative told here, the one to which almost all others relate, is that of the emergence of ‘machinery in the Canadian home’. As the 20th century dawned, Canadians, accustomed to their resource-based, extractive economy were used to transportation, traction and motive power machines in farm, mill and factory, where they seemed to rightfully belong. With the 1920’s, however, all that was about to change ‘ and change dramatically Here-to-for, the familiar motive power, rotating machines of farm, mill and factory were driven by central station power plants, water, steam and later internal combustion engines. But it was with the advent of motive power packaged in unitary, moveable forms, as in the ‘stationary’, gasoline engine [explosion engine] and the electric motor that a new era in motive power was made possible for home, as well as for farm, mill and factory applications It was principally the fractional horsepower, single phase, induction electric motor [see note #1] that made possible the introduction of machinery into the home, and with it ‘the end of quiet’ [see historical artifacts Classification Group 16,00, see Reference #1].

With the introduction of self powered machines into the home also came the introduction of automated, self regulating machinery, machinery that would turn iteself on and off, without the touch of human hand - the refrigerator, oil burner and water pump. These automated, inanimate objects also introduced new rhythms into the home, each with its distinctive hum and beat, each coming on and off with its own unique operating rhythm. The aroma of oils, vapours and materials, once foreign in the household, would also follow. The 20th century ‘electro- mechanical’ Canadian home had arrived, much the same as the digital Canadian home would arrive in little more than half a century later ‘ changing all. The consequences were profound, spelled out in terms of the social, cultural and economic changes wrought.

Donor:

G. Leslie Oliver, The T. H. Oliver HVACR Collection

HHCC Storage Location:

Tracking:

Bibliographic References:

For an account of the construction, operation, installation and servicing of fuel oil pump assemblies see ‘Better Oilheating, A service Guide, Operation and Maintenance of Oil Burners, Second Edition, 1959, Fueloil and Heat, N.Y.